What is CNC control system

The CNC control system is an important part of the high-speed machining center, which determines the speed, precision and surface quality of the machine tool to a large extent. Therefore, for high-speed machine tools that process free-form surfaces of molds, the performance of the numerical control system is particularly important.

Advantages of CNC turning and milling machine tools

The CNC turning and milling machine tool is a very precise production and processing tool. Compared with ordinary lathes, it has absolute advantages in terms of accuracy, efficiency, and qualification rate. Compared with ordinary lathes, turning and milling composite machine tools can greatly improve product quality and production efficiency, improve the competitiveness of enterprises, and promote development.

Double spindle swiss CNC Lathe provides important opportunity for the transformation and upgrading

With the continuous progress of technology, various machinery and equipment are also constantly undergoing innovation and upgrading. Among them, the double spindle Swiss CNC lathe is such a new type of equipment, which integrates multiple technologies and fully demonstrates the strong strength in the field of mechanical processing. So, what is a double spindle Swiss CNC lathe? What are its characteristics and advantages?

The new rise of superhard cutting tools

Our country is a newly emerging modern manufacturing country. In recent years, the country has attached great importance to the research and development of high-speed cutting technology for superhard tools. Industrial materials represented by high-temperature alloys, titanium alloys, stainless steel, isostatic graphite, silicon materials,

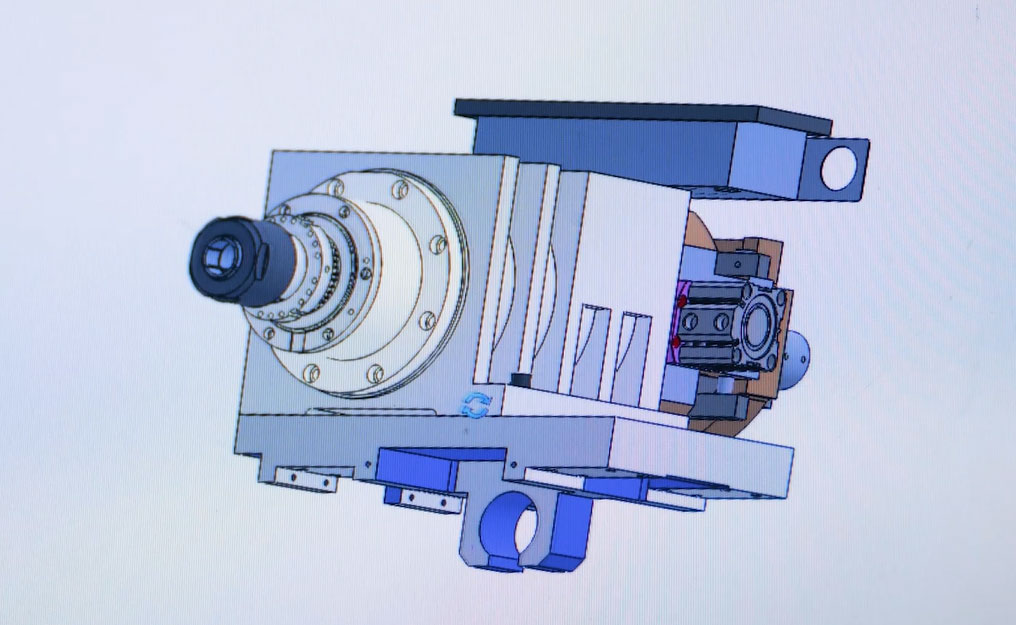

The structural design advantages of high-speed machine tools lead the machine tool industry

Judging from the current development of the machine tool industry in high-speed machining centers, compared with the three-axis high-speed machining that appeared in the mid-to-late 1990s, it can be said that the number of axes and linear drive

Features and advantages of CNC line rail CNC lathe

The rail usually refers to the rolling guide rail, and this type of element is often called "linear guide rail". The linear guide itself is divided into two parts: the slide rail and the slider. There are internal circulating balls or rollers in the slide block, and the length of the slide rail can be customized. It is a modular component, which is a standardized and serialized unique product produced by a special manufacturer. It can be installed on the machine tool, and can be disassembled and

Preparation before test run of CNC lathe

The bed CNC lathe is coated with anti-rust oil or anti-rust paint to protect the guide rail surface and processing surface when it leaves the factory. Clean the dust on the outer surface of the machine tool. Apply lubricant specified for machine tools on each sliding surface and working surface.

How to ensure the working accuracy and extend the service life of CNC lathes?

CNC CNC lathe with inclined bed is a CNC lathe with high speed, high precision and high reliability. The hydraulic chuck or nozzle is used for clamping, which makes clamping more convenient and convenient, with higher precision and less labor.

Advantages of CNC lathes

CNC lathe is a CNC lathe with good flexibility and high efficiency. A good mechanical equipment is not perfect. It has good advantages and bad disadvantages. The editor below will introduce to you the advantages and disadvantages of automatic lathes.

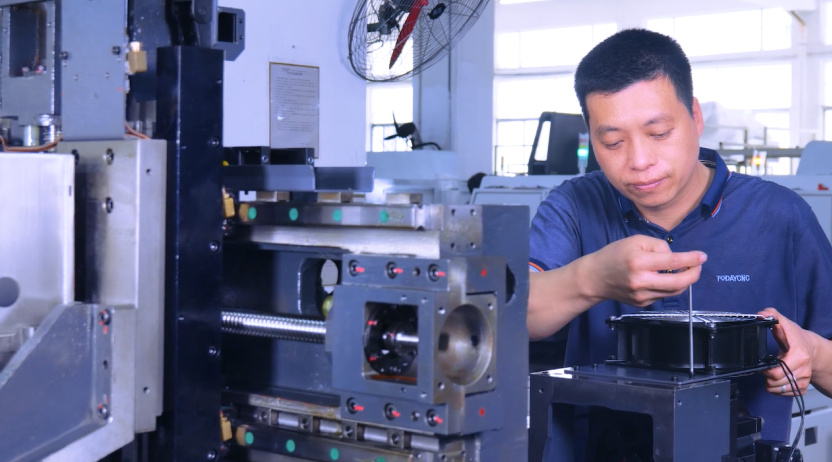

How to select tool holders and tools for CNC machine tools

The selection of CNC lathe tool holders and cutting tools is one of the important contents in CNC machine tool configuration, because the selection of CNC lathe tool holders and cutting tools not only affects the production efficiency of CNC machine tools, but also directly affects the processing quality of parts. Optimizing the tool and tool holder system according to the performance of CNC machine tools or machining centers and centering machines and the characteristics of CNC machining techno

How to solve the problem of continuous winding and cutting of chips when cutting grooves on CNC lat

The problem of cutting and coiling is often encountered in grooving production and processing, which easily leads to poor quality of steel parts, resulting in the failure of the process to be carried out, and there is no way to improve it, and the processing efficiency is not high, which is very headache.