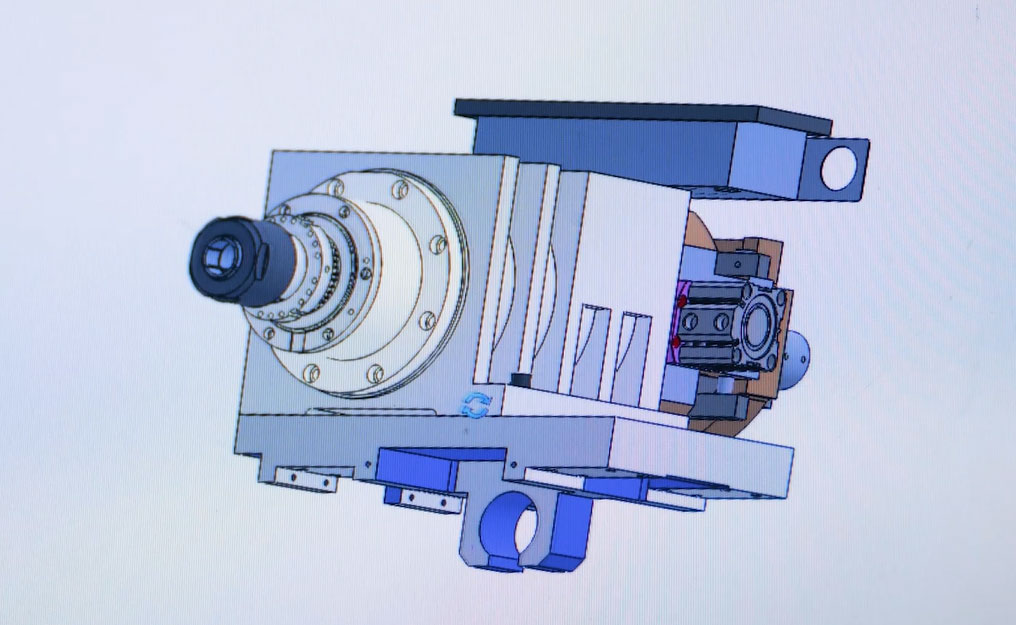

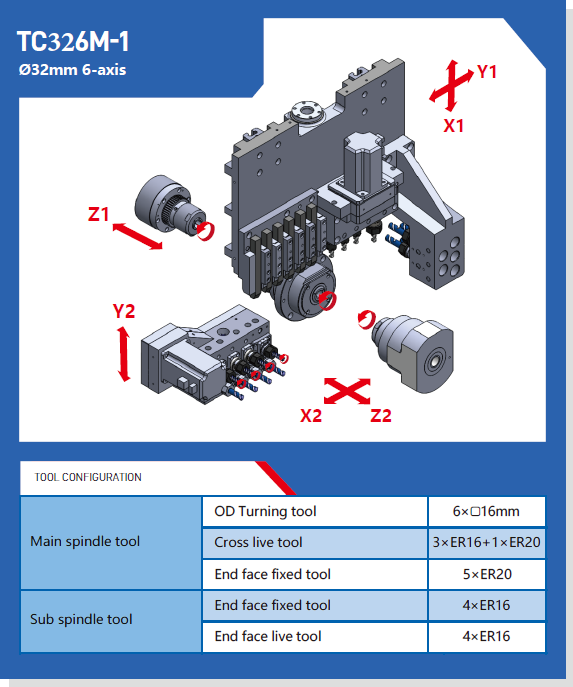

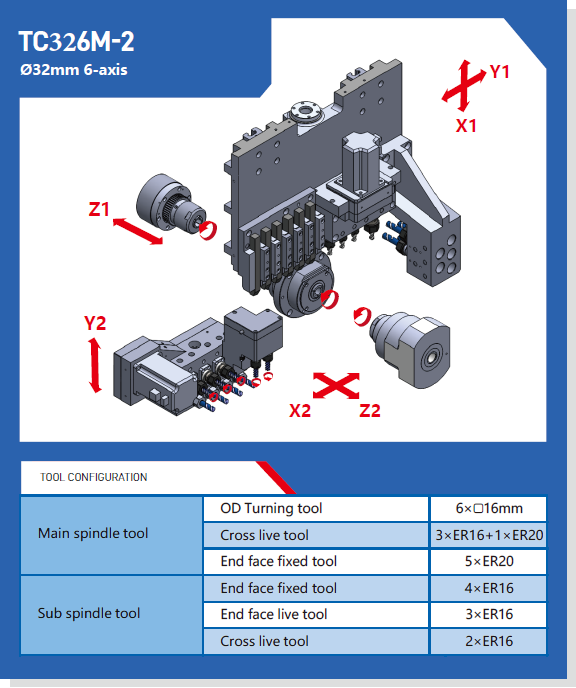

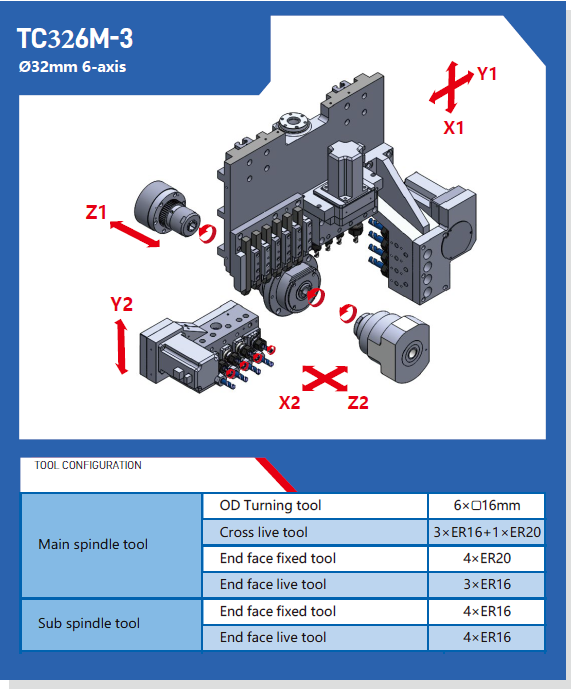

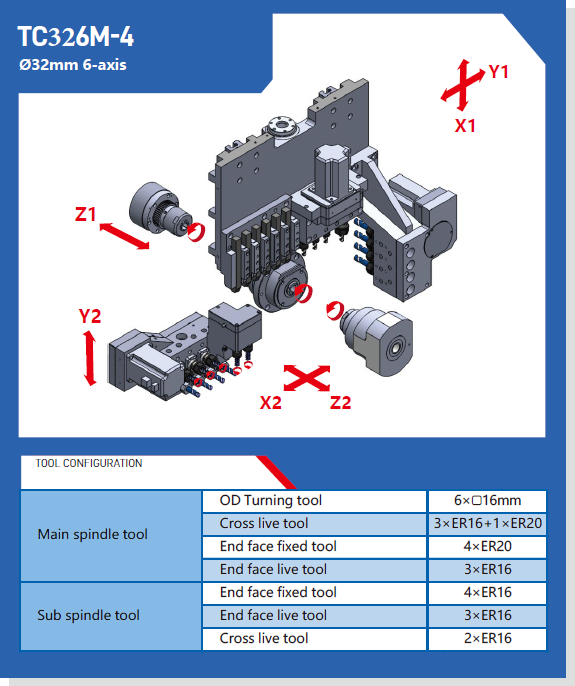

TC326M

Double spindle

6-axis function

Max machining diameter: 32mm

Mechanical spindle

6-axis function

Max machining diameter: 32mm

Mechanical spindle

■ Each axis equipped with imported high-precision linear guide,ball screws and precise bearings.

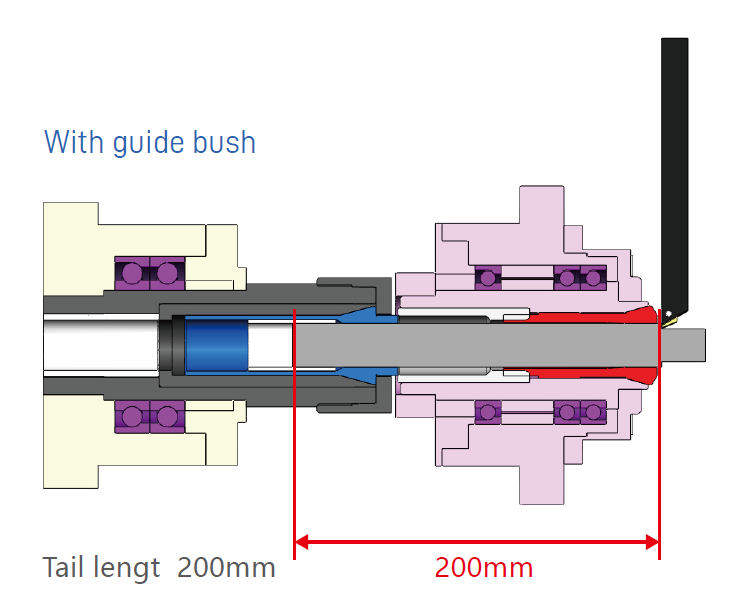

■ Using synchronous guide bush structure,realize high-speed and high-precision machining.

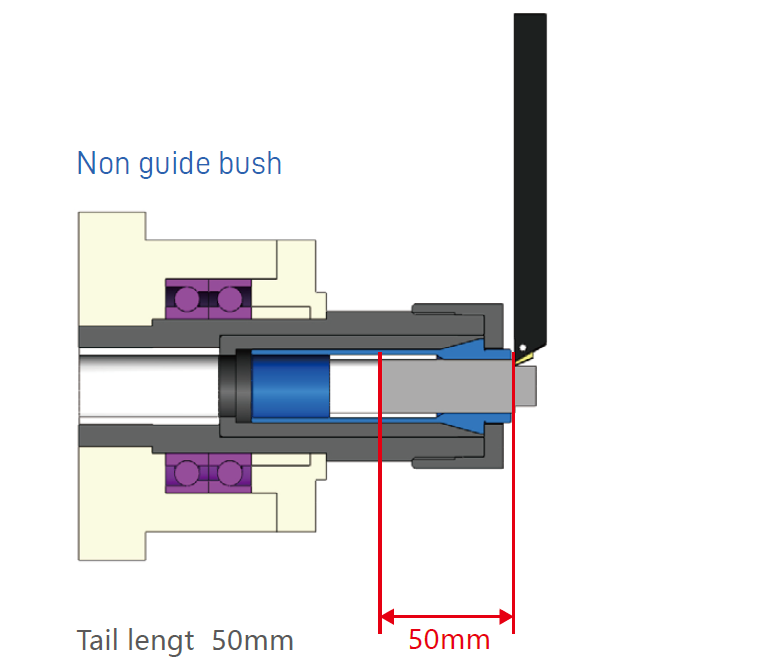

■ With guide bush or without guide bush switching flexiblely to meet different needs of processing.

■ Key components with gas sealing structure, oil and slag prevention, improving service life and stability.

■ Select high torque motor, high rigidity and high strength slipway for each axis and tool installation seat to meet the requirements of large cutting volume and high processing efficiency.

■ High scalability, tool quantities matched with different requirements of processing, reaching great cost-effective.

■ Multiple ER20 tools can be installed to increase the machining range.

■ Using synchronous guide bush structure,realize high-speed and high-precision machining.

■ With guide bush or without guide bush switching flexiblely to meet different needs of processing.

■ Key components with gas sealing structure, oil and slag prevention, improving service life and stability.

■ Select high torque motor, high rigidity and high strength slipway for each axis and tool installation seat to meet the requirements of large cutting volume and high processing efficiency.

■ High scalability, tool quantities matched with different requirements of processing, reaching great cost-effective.

■ Multiple ER20 tools can be installed to increase the machining range.

■ SYNTEC numerical control system

■ Main pneumatic chucking device

■ Movable guide bush

■ Synchronal rotary guide bush device

■ Live tool

■ Workpiece belt conveyor

■ Y2 tool holder

■ Main pneumatic chucking device

■ Movable guide bush

■ Synchronal rotary guide bush device

■ Live tool

■ Workpiece belt conveyor

■ Y2 tool holder

■ Non guide bush

■ MITSUBISHI numerical control system

■ FANUC numerical control system

■ High pressure pump

■ Oil mist collector

■ Chip conveyor

■ Long workpiece collector

■ MITSUBISHI numerical control system

■ FANUC numerical control system

■ High pressure pump

■ Oil mist collector

■ Chip conveyor

■ Long workpiece collector