TC385

Double spindle

5-axis function

Max machining diameter: 38mm

Motorized spindle

5-axis function

Max machining diameter: 38mm

Motorized spindle

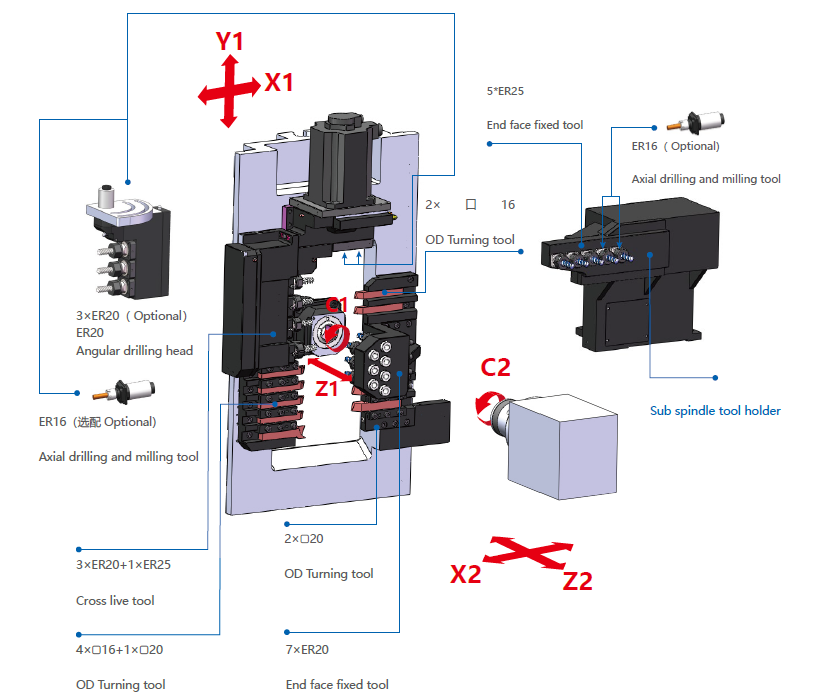

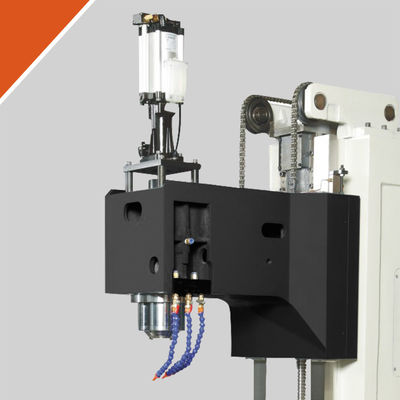

| DOUBLE SPINDLE AXIAL DRILLING AND MILLING TOOL INSTALLATION DIAGRAM |

|

| Cross live tool | 4×ER16 Live tool |

| Fixed angle holder (end face) | 4×ER16 Fixed tool |

| Angle adjustment range holder ( 0-90° ) | 3×ER16 Live tool |

| Model |

|

TC385-1 | TC385-2 | |

|

|

|

5-axis,dual spindle | 5-axis,dual spindle | |

| NC system |

|

SYNTEC 220TB | SYNTEC 220TB | |

| Lathe rated power | kw | 25 | 25 | |

| Machining range | ||||

| Maximum machining diameter | mm | φ38 | φ38 | |

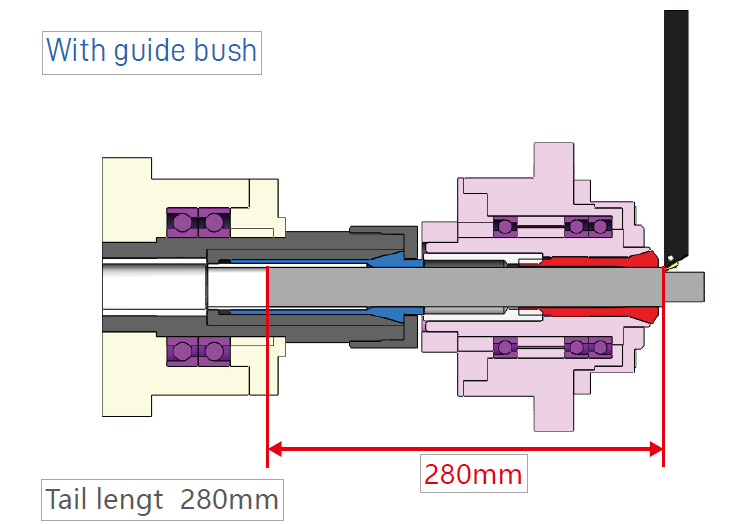

| Maximum machining length (one-time clamping)With guide bush | mm | 320 | 320 | |

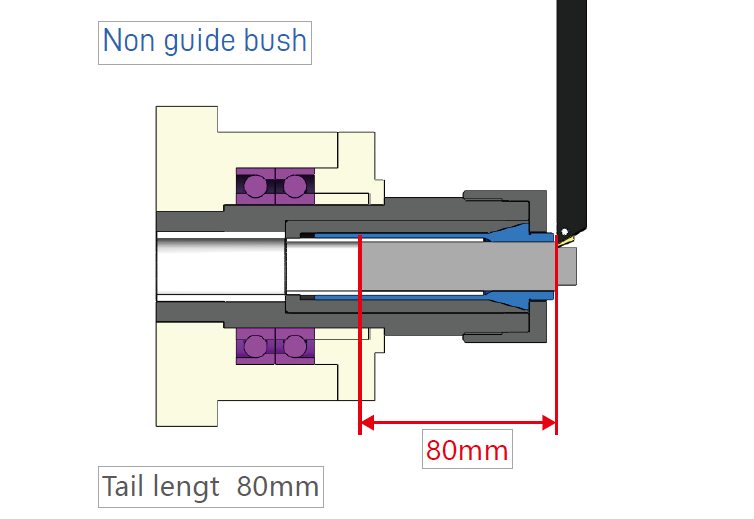

| Maximum machining length (one-timeclamping)Non guide bush | mm | 85 | 85 | |

| Main spindle power | kw | 10 | 10 | |

| Sub spindle power | kw | 10 | 10 | |

| Main spindle max through hole dia | mm | φ42 | φ42 | |

| Main/sub spindle rev speed | rpm | 6000 | 6000 | |

| Sub spindle max clamping dia | mm | φ38 | φ38 | |

| Sub spindle max through hole dia | mm | φ42 | φ42 | |

| Max tool installed qty |

|

25 | 25 | |

| Main spindle tool | ||||

| OD Turning tool | Qty x Model |

|

6✖▢16+3✖▢20 | 6✖▢16+3✖▢20 |

| Side- Live tool | Qty x Model |

|

3✖ER20+1✖ER25 | 3✖ER20+1✖ER25 |

| Drilling dia | mm | φ16 | φ16 | |

| Tapping/Threading die dia |

|

M8 | M8 | |

| Live tool rev speed | rpm | 5000 | 5000 | |

| Live tool power | kw | 2.3 | 2.3 | |

| End face fixed tool | Qty x Model |

|

7✖ER20 | 7✖ER20 |

| Drilling dia | mm | φ13 | φ13 | |

| Tapping/Threading die dia |

|

M10 | M10 | |

| Angular drilling head | mm | —— | —— | |

| Axial drilling and milling tool | mm | —— | —— | |

| Sub spingdle tool | ||||

| End face fixed tool | Qty x Model | mm | 5✖ER25 | 3✖ER25 |

| Drilling dia | mm | φ16 | φ16 | |

| Tapping/Threading die dia |

|

M10 | M10 | |

| Axial drilling and milling tool |

|

—— | 2✖ER16 | |

| Rapid feed speed | m/min | 18(X1)24(X2/Y1/Z1/Z2) | 18(X1)24(X2/Y1/Z1/Z2) | |

| Feed motor power | kw | 1.7 | 1.7 | |

| The power capacity | kva | 25 | 25 | |

| Air pressure device | mpa | 0.6 | 0.6 | |

| Weight | kg | 4800 | 4800 | |

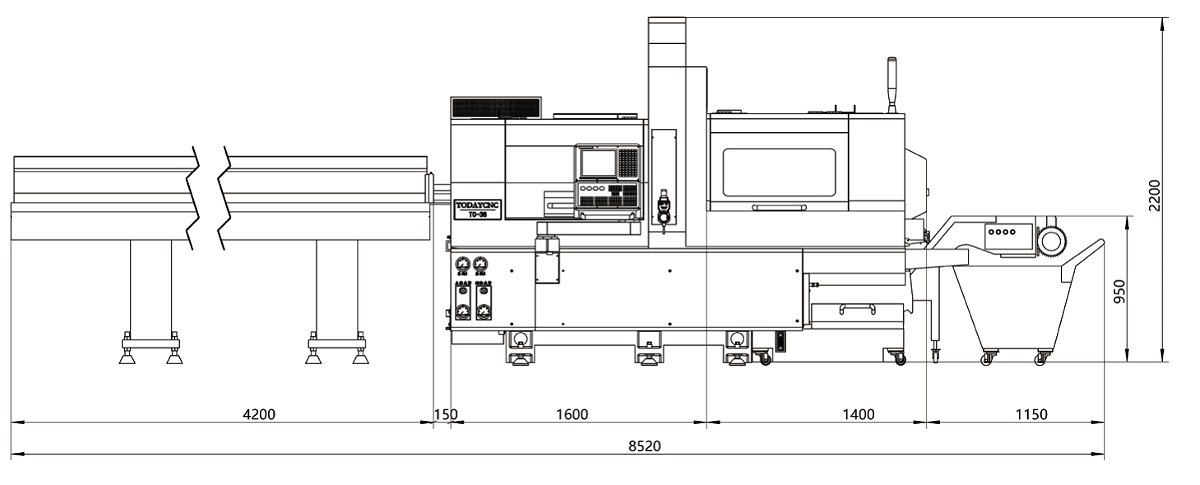

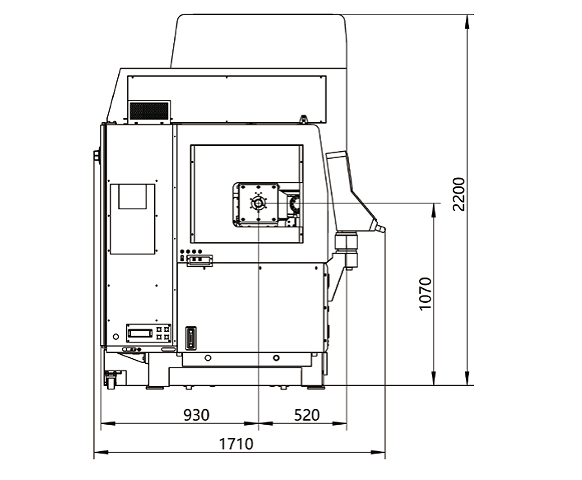

| Dimensions | mm | 3000*1450*2200 | 3000*1450*2200 | |

Features

■ Each axis uses 30 type P-precision roller guide rail and 32 type double nut C3 screw.

■ Built-in electric spindle,hydraulic clamping,ensure high precision machining.

■ Main spindle clamping is compatible with both Push forward and pull back modes, not necessary requires large diameter grinding materials.

■ Main spindle primary processing length is 320mm with guide bush.

■ Main spindle side milling adopts ER25+ER20 with 2.3 high-power motors, combined with the spindle hydraulic brake, to improve milling efficiency and rigidity.

■ Main spindle tool holder adopts rectangular-ambulatory-plane layout,reduce machine volume,enhance the rigidity of the tool holder structure, and achieve fast tool change speed.

■ Each axis uses 30 type P-precision roller guide rail and 32 type double nut C3 screw.

■ Built-in electric spindle,hydraulic clamping,ensure high precision machining.

■ Main spindle clamping is compatible with both Push forward and pull back modes, not necessary requires large diameter grinding materials.

■ Main spindle primary processing length is 320mm with guide bush.

■ Main spindle side milling adopts ER25+ER20 with 2.3 high-power motors, combined with the spindle hydraulic brake, to improve milling efficiency and rigidity.

■ Main spindle tool holder adopts rectangular-ambulatory-plane layout,reduce machine volume,enhance the rigidity of the tool holder structure, and achieve fast tool change speed.

STANDARD CONFIGURATION

■ Short workpiece collector

■ Workpiece belt conveyor

■ Synchronal rotary guide bush device

■ Main spindle cross 4 axis live tool

■ Cut off tool breakage detector

■ Non guide bush

■ Short workpiece collector

■ Workpiece belt conveyor

■ Synchronal rotary guide bush device

■ Main spindle cross 4 axis live tool

■ Cut off tool breakage detector

■ Non guide bush

OPTIONAL CONFIGURATION

■ Angular drilling head

■ Long workpiece collector

■ High pressure pump

■ Oil mist collector

■ Chip conveyor

■ Axial drilling and milling tool

■ Angular drilling head

■ Long workpiece collector

■ High pressure pump

■ Oil mist collector

■ Chip conveyor

■ Axial drilling and milling tool

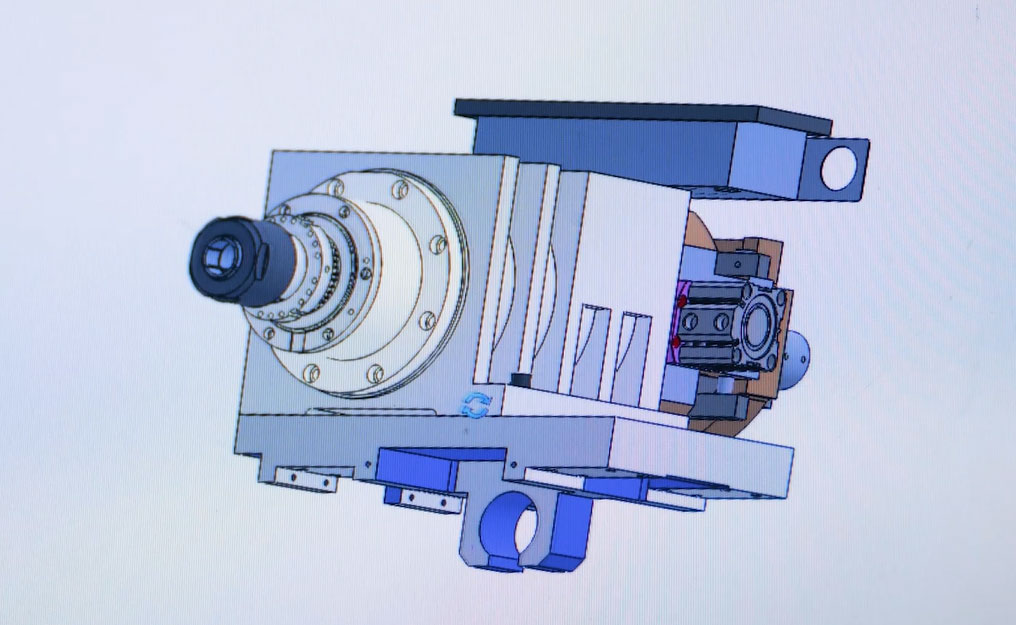

Machine head

Strengthened cross-ribs to increase bending and torsion resistance.

Strengthened cross-ribs to increase bending and torsion resistance.