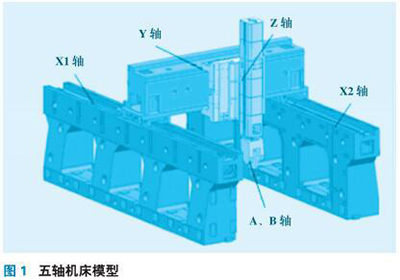

New algorithm for error modeling and compensation analysis of five-axis machine tools

Global competition forces manufacturing companies to pay more and more attention to product processing efficiency and accuracy. Product accuracy is largely determined by the accuracy of machine tools. Five-axis CNC machine tools can

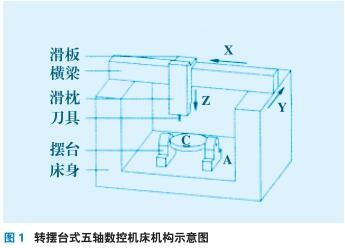

Geometric error detection and compensation of five-axis CNC machine tool rotary center

Five-axis CNC machine tools are the most important processing equipment in the equipment manufacturing industry. They can be used to process various complex curved surfaces. With the continuous improvement of workpiece processing quality requirements, how to improve the processing accuracy of five-axis CNC machine tools has become a hot topic.

High-speed and high-precision machine tool thermal analysis and thermal design technology Source:

With the continuous advancement of related technologies such as design, manufacturing, assembly and materials of CNC machine tools and parts, the proportion of geometric errors, tool wear, servo and other errors in the overall errors of CNC machine tools is gradually decreasing. Under

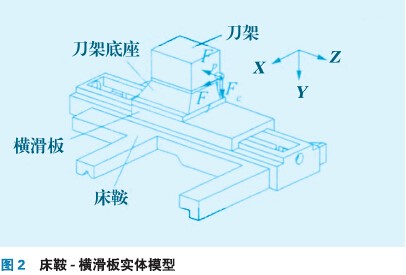

Performance analysis of slide rail connection surface based on machine tool stiffness introduction

In order to achieve certain motion functions of machine tools, the components are combined by connecting surfaces. The connection surface is divided into fixed connection surface (such as bolt connection), semi-fixed connection surface

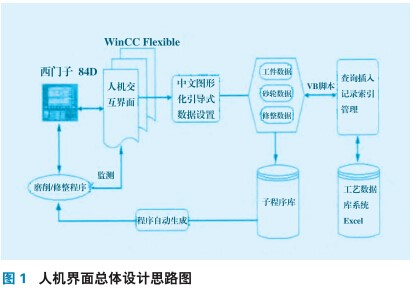

Application of WinCC+Flexible in CNC machine tool interface development

At present, Siemens CNC systems are increasingly widely used in my country's machine tool industry. The standard human-computer interaction interface of the Siemens 840D CNC system

Modeling and simulation of dynamic characteristic parameters of joint surface of CNC machine tools

Since there are joint surfaces between machine tool components, the "flexible" nature of the joint surfaces that both stores and consumes energy greatly affects the static and dynamic characteristics of the entire machine tool. The stiffness and damping between the combined surfaces, especially the damping, are often greater than the elasticity and damping of the structure

Analysis of dynamic characteristics of CNC machine tool spindle system

The CNC machine tool spindle system includes components such as spindle, bearings, tool holders, tools (or workpieces), etc., and is an important subsystem of CNC machine tools. The dynamic characteristics of the spindle system directly affect the machining accuracy, surface roughness and productivity of the workpiece. Therefore, the dynamic design and analysis of the spindle system has attracted widespread attention from the business community and scholars. In particular, in recent years, the d

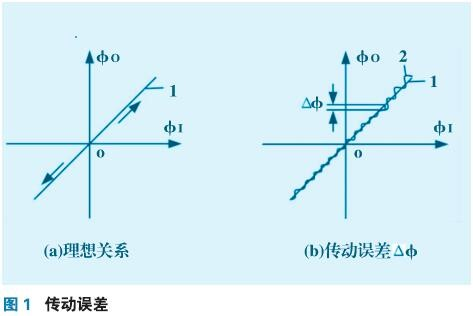

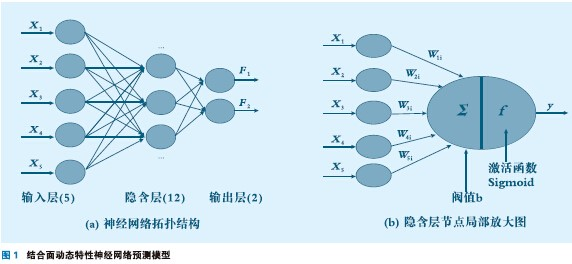

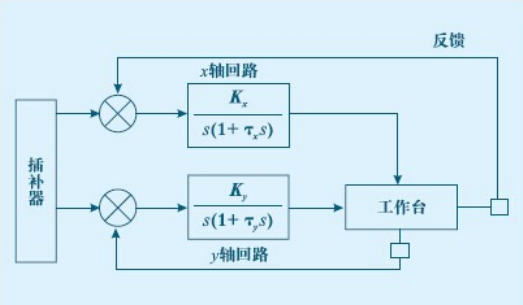

Precision analysis and control research on machine tool feed system

The feed system of CNC machine tools is mainly the servo feed method of servo motor + ball screw. The rotary motion output by the servo motor is converted into linear motion of the controlled object through a series of intermediate transmission devices such as couplings and ball screw pairs. The structural block diagram of its mechanical system is shown in Figure 1, and the mathematical model is:

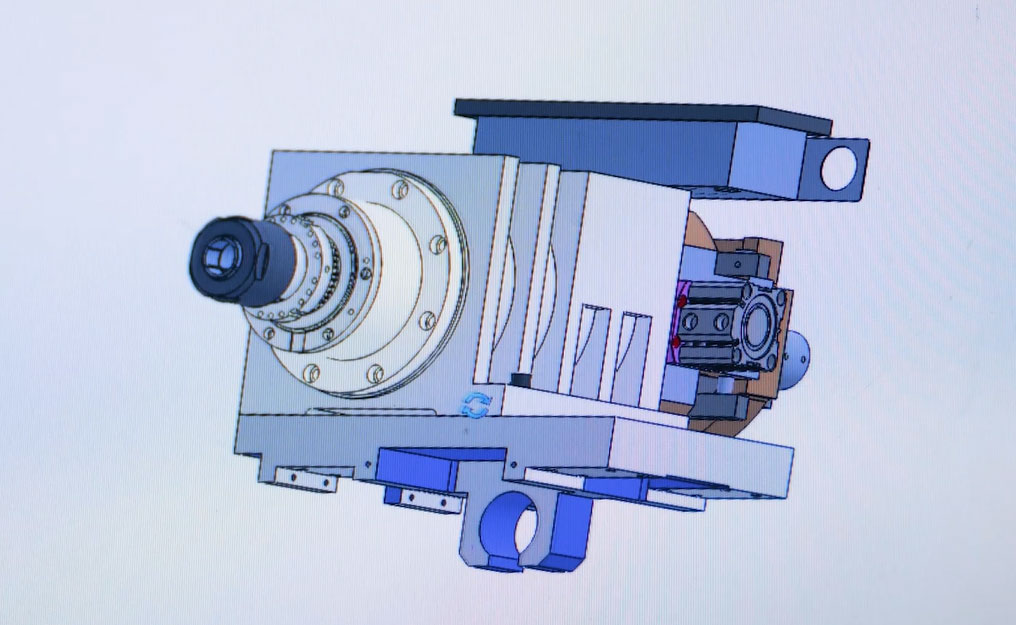

Research on spatial error modeling of universal spindle head of five-axis CNC machine tools

With the extensive application of free-form surfaces, modern manufacturing industry has an increasing demand for five-axis machine tools. Five-axis machine tools can be divided into several types according to different structures: double turntable type, turntable plus swing axis type, universal spindle head type, etc. The two rotary axes of the universal spindle head type CNC machine tool are both located on the spindle. Since the universal spindle head adds two rotating axes compared to other t

What is CNC control system

The CNC control system is an important part of the high-speed machining center, which determines the speed, precision and surface quality of the machine tool to a large extent. Therefore, for high-speed machine tools that process free-form surfaces of molds, the performance of the numerical control system is particularly important.

Advantages of CNC turning and milling machine tools

The CNC turning and milling machine tool is a very precise production and processing tool. Compared with ordinary lathes, it has absolute advantages in terms of accuracy, efficiency, and qualification rate. Compared with ordinary lathes, turning and milling composite machine tools can greatly improve product quality and production efficiency, improve the competitiveness of enterprises, and promote development.

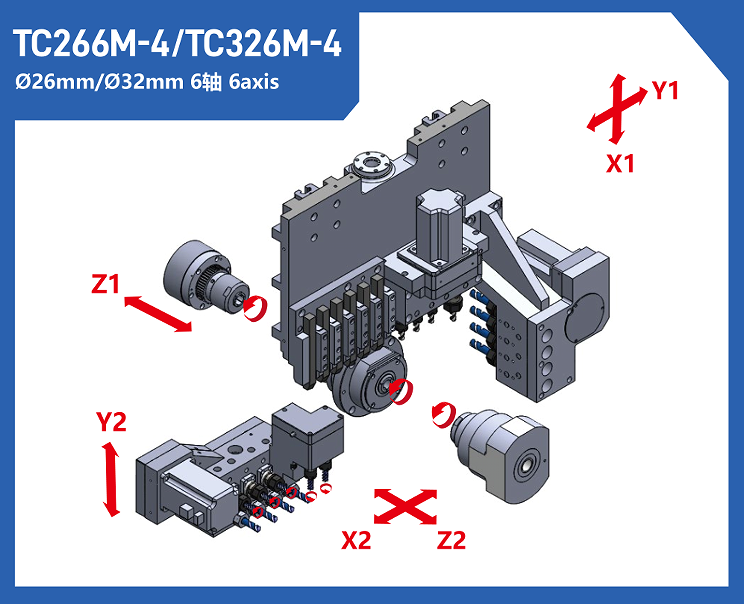

Double spindle swiss CNC Lathe provides important opportunity for the transformation and upgrading

With the continuous progress of technology, various machinery and equipment are also constantly undergoing innovation and upgrading. Among them, the double spindle Swiss CNC lathe is such a new type of equipment, which integrates multiple technologies and fully demonstrates the strong strength in the field of mechanical processing. So, what is a double spindle Swiss CNC lathe? What are its characteristics and advantages?

The new rise of superhard cutting tools

Our country is a newly emerging modern manufacturing country. In recent years, the country has attached great importance to the research and development of high-speed cutting technology for superhard tools. Industrial materials represented by high-temperature alloys, titanium alloys, stainless steel, isostatic graphite, silicon materials,

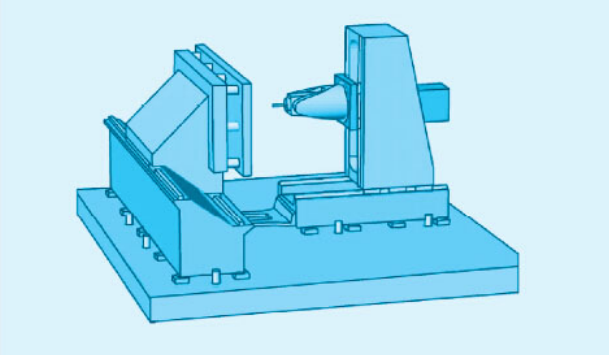

The structural design advantages of high-speed machine tools lead the machine tool industry

Judging from the current development of the machine tool industry in high-speed machining centers, compared with the three-axis high-speed machining that appeared in the mid-to-late 1990s, it can be said that the number of axes and linear drive

Features and advantages of CNC line rail CNC lathe

The rail usually refers to the rolling guide rail, and this type of element is often called "linear guide rail". The linear guide itself is divided into two parts: the slide rail and the slider. There are internal circulating balls or rollers in the slide block, and the length of the slide rail can be customized. It is a modular component, which is a standardized and serialized unique product produced by a special manufacturer. It can be installed on the machine tool, and can be disassembled and

Preparation before test run of CNC lathe

The bed CNC lathe is coated with anti-rust oil or anti-rust paint to protect the guide rail surface and processing surface when it leaves the factory. Clean the dust on the outer surface of the machine tool. Apply lubricant specified for machine tools on each sliding surface and working surface.

How to ensure the working accuracy and extend the service life of CNC lathes?

CNC CNC lathe with inclined bed is a CNC lathe with high speed, high precision and high reliability. The hydraulic chuck or nozzle is used for clamping, which makes clamping more convenient and convenient, with higher precision and less labor.

Advantages of CNC lathes

CNC lathe is a CNC lathe with good flexibility and high efficiency. A good mechanical equipment is not perfect. It has good advantages and bad disadvantages. The editor below will introduce to you the advantages and disadvantages of automatic lathes.

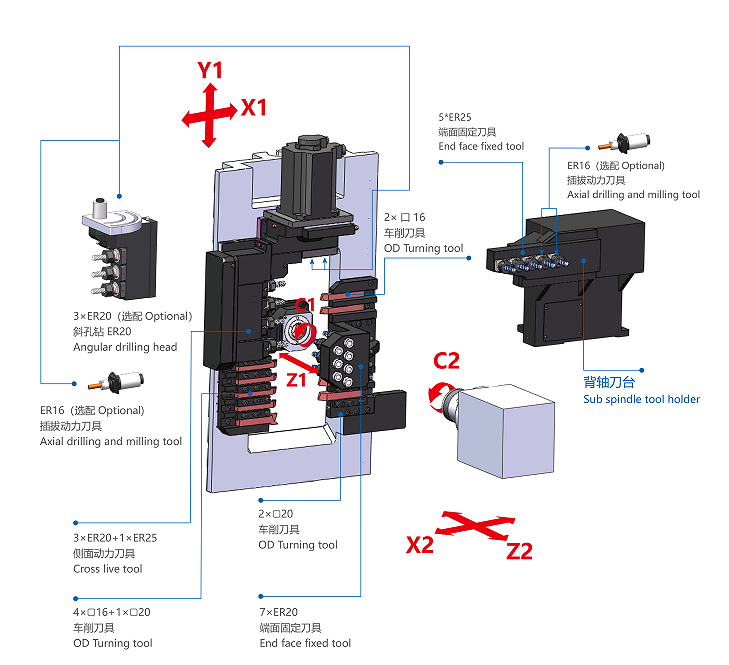

How to select tool holders and tools for CNC machine tools

The selection of CNC lathe tool holders and cutting tools is one of the important contents in CNC machine tool configuration, because the selection of CNC lathe tool holders and cutting tools not only affects the production efficiency of CNC machine tools, but also directly affects the processing quality of parts. Optimizing the tool and tool holder system according to the performance of CNC machine tools or machining centers and centering machines and the characteristics of CNC machining techno

How to solve the problem of continuous winding and cutting of chips when cutting grooves on CNC lat

The problem of cutting and coiling is often encountered in grooving production and processing, which easily leads to poor quality of steel parts, resulting in the failure of the process to be carried out, and there is no way to improve it, and the processing efficiency is not high, which is very headache.

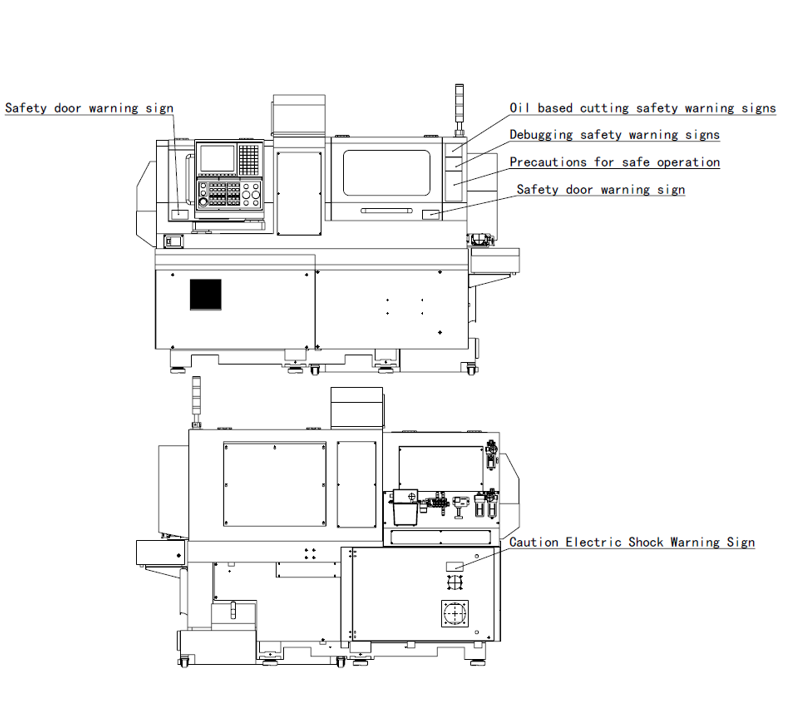

Operational safety

Before carrying out the trial operation, you must read this manual and have a comprehensive understanding of the machine first. If possible, it is better to wait for the factory's after-sales service to arrive before the trial operation; Strictly following operating procedures can not only give you a safe working environment for operators and but also increase productivity.

Safety during installation, commissioning and maintenance

When installing and debugging the machine, pay attention to the following matters to prevent personal injury or damage to the machine:

Safety devices

Spindle speed change detection device

Lubricating oil level detection device

Coolant flow detection device

Security door lock

If the axis speed changes by more than ±15% due to overload or external influence, an alarm will occur.

Fire prevention measures

Please observe the following precautions to prevent fire:

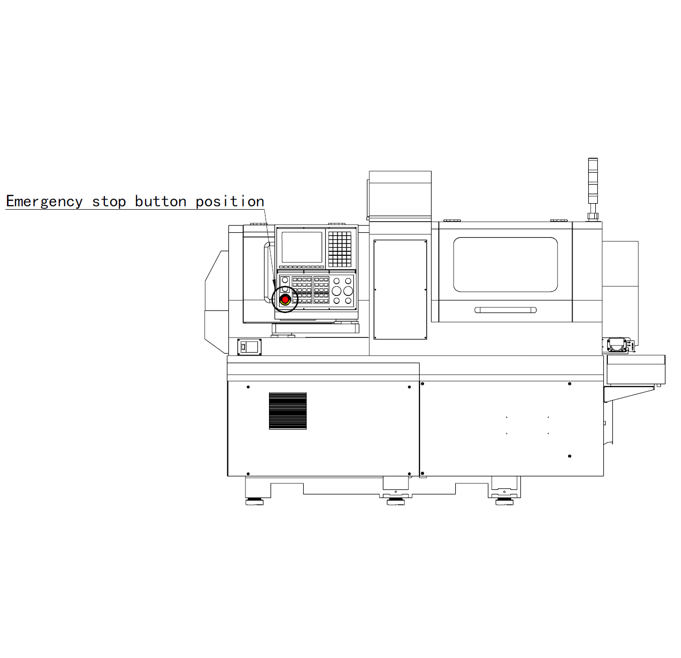

Emergency handling

When a situation arises and requires evacuation

When encountering an emergency such as fire, earthquake, or lightning and you need to evacuate, please follow these steps:

Transportation of machine

CNC lathe consists of three major components: main machine, electrical control cabinet and pneumatic power unit. In order to ensure the accuracy of the machine, it is particularly convenient to transport and does not need to be disassembled.

Choice of installation location

In order to ensure the accuracy of the machine, circuit interference from power terminals, ground, air, temperature, humidity, ventilation, lighting and other machines must be fully considered during installation. The location where the machine is installed should meet the following requirements:

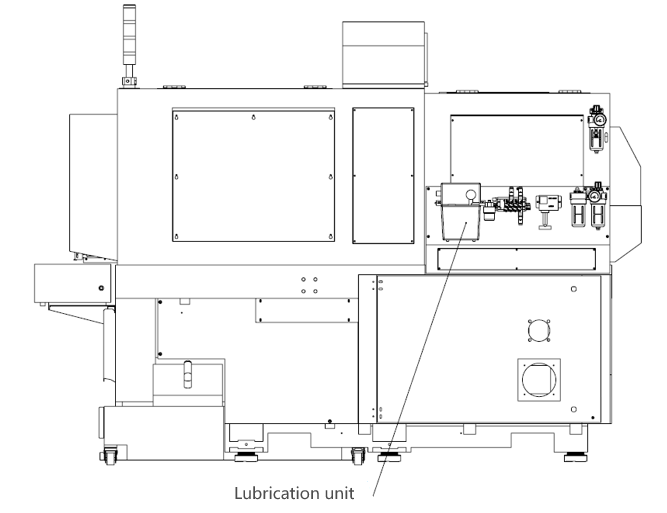

Machine tool lubrication

Carry out thorough and proper lubrication of the machine tool according to the lubrication diagram. It is recommended to use the lubricating oil types listed in the following table for lubrication.

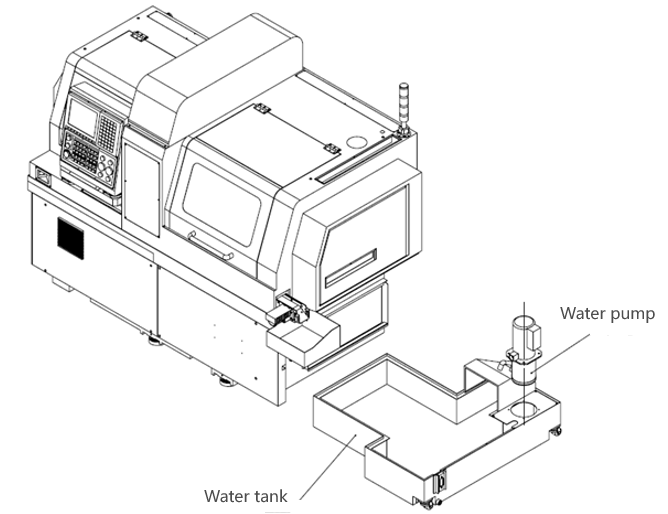

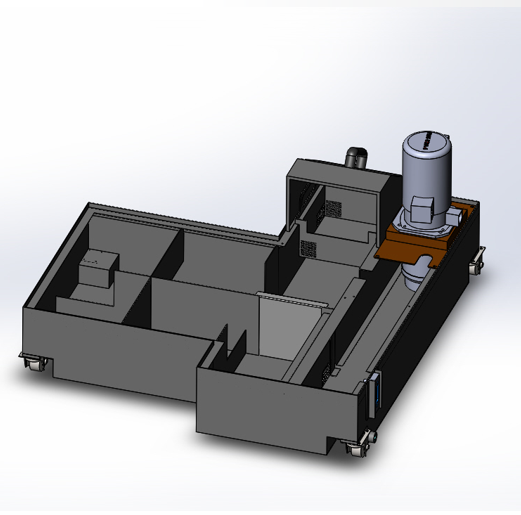

Machine cooling

The cooling pump is a separately installed electric pump.

(2)The structure of the cooling pump adopts a mechanical shaft seal and a greased dust cover ball bearing. Therefore, its