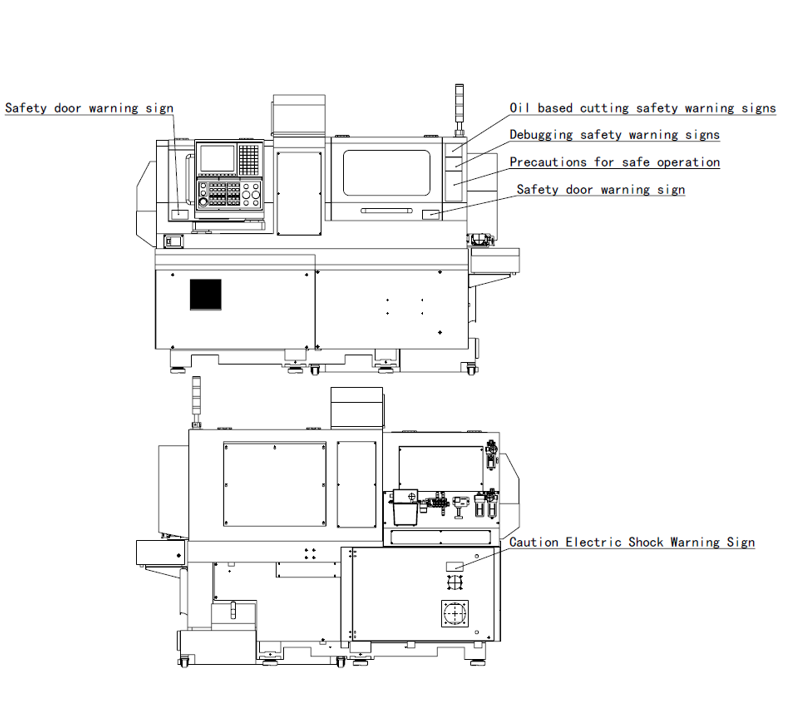

Operational safety

Before carrying out the trial operation, you must read this manual and have a comprehensive understanding of the machine first. If possible, it is better to wait for the factory's after-sales service to arrive before the trial operation; Strictly following operating procedures can not only give you a safe working environment for operators and but also increase productivity.

Safety during installation, commissioning and maintenance

When installing and debugging the machine, pay attention to the following matters to prevent personal injury or damage to the machine:

Safety devices

Spindle speed change detection device

Lubricating oil level detection device

Coolant flow detection device

Security door lock

If the axis speed changes by more than ±15% due to overload or external influence, an alarm will occur.

Fire prevention measures

Please observe the following precautions to prevent fire:

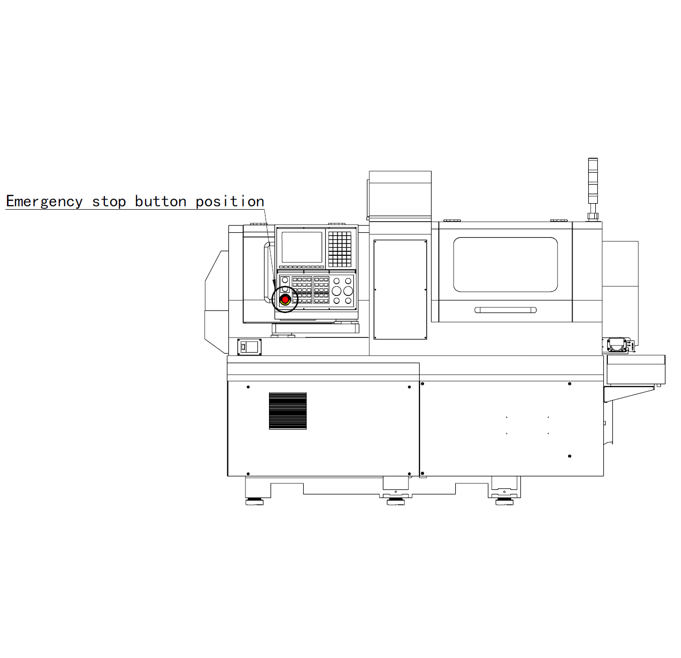

Emergency handling

When a situation arises and requires evacuation

When encountering an emergency such as fire, earthquake, or lightning and you need to evacuate, please follow these steps:

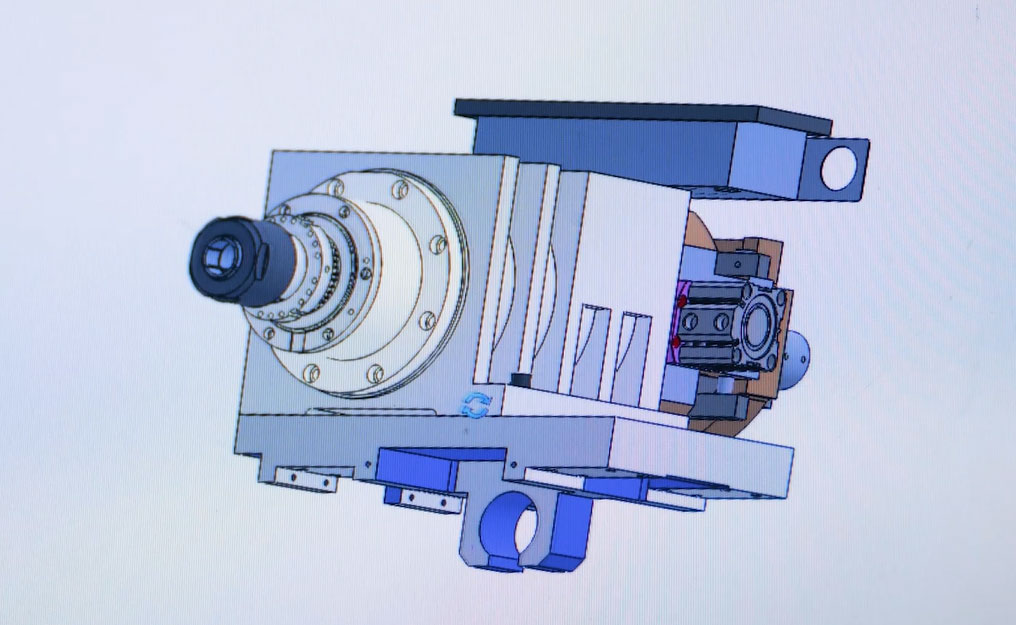

Transportation of machine

CNC lathe consists of three major components: main machine, electrical control cabinet and pneumatic power unit. In order to ensure the accuracy of the machine, it is particularly convenient to transport and does not need to be disassembled.

Choice of installation location

In order to ensure the accuracy of the machine, circuit interference from power terminals, ground, air, temperature, humidity, ventilation, lighting and other machines must be fully considered during installation. The location where the machine is installed should meet the following requirements:

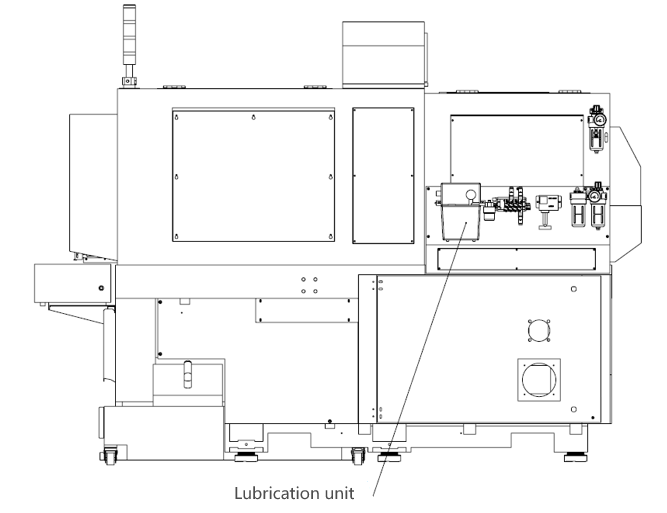

Machine tool lubrication

Carry out thorough and proper lubrication of the machine tool according to the lubrication diagram. It is recommended to use the lubricating oil types listed in the following table for lubrication.

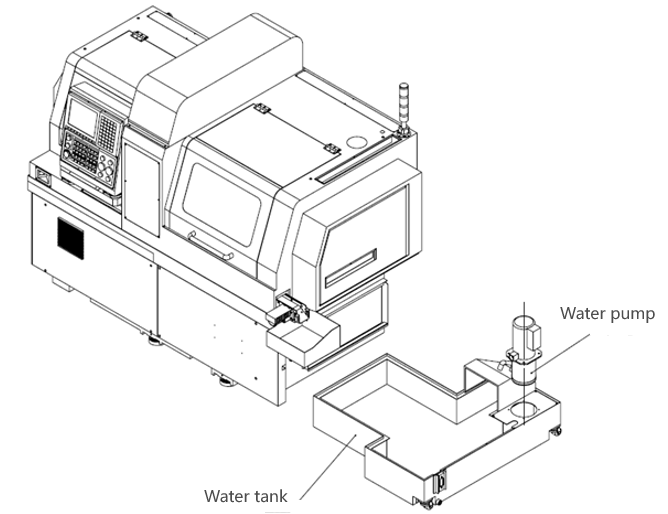

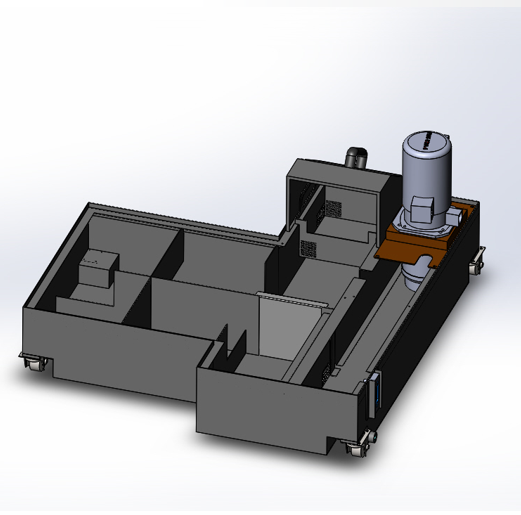

Machine cooling

The cooling pump is a separately installed electric pump.

(2)The structure of the cooling pump adopts a mechanical shaft seal and a greased dust cover ball bearing. Therefore, its

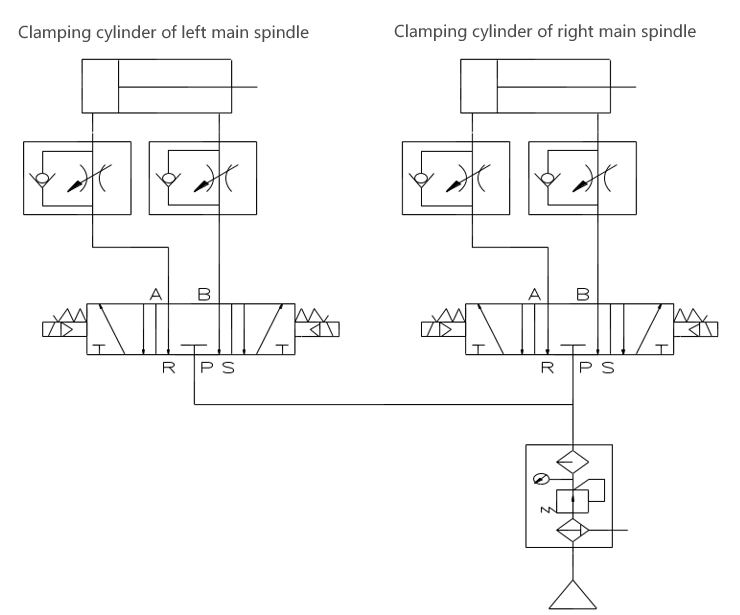

Pneumatic system

The air source is the power source of the machine pneumatic device. Users should configure specifications according to their actual conditions.

Half-year inspection

The half-year inspection is mainly for consumables that are easily overlooked and do not need to be replaced frequently. Do not ignore these inspection items, otherwise the machine may suffer serious malfunctions.

Things to pay attention to during CNC lathe processing

"Look" "Listen" "Smell" "Ask"