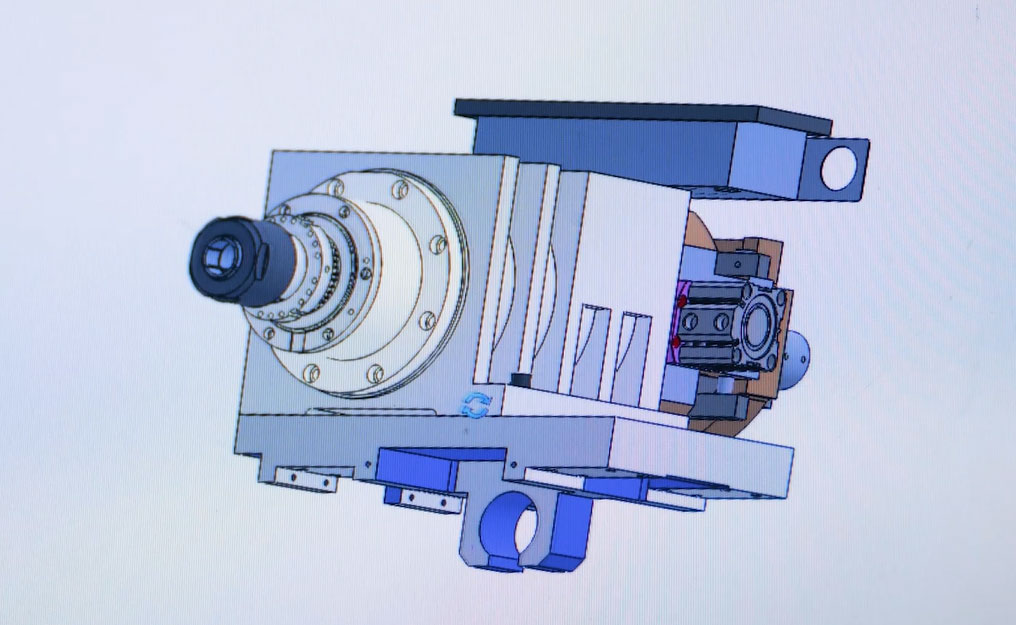

CNC lathe consists of three major components: main machine, electrical control cabinet and pneumatic power unit. In order to ensure the accuracy of the machine, it is particularly convenient to transport and does not need to be disassembled.

1.There are two methods of transporting machine tools:

(1)Driving lifting requires special spreaders. Unless under special circumstances, this book recommends using a forklift;

(2)Forklift;;

This manual only introduces the method of lifting with a forklift. If it is necessary to use a crane for lifting, please contact our company before sending the machine.

2. Forklift transportation

2. Forklift transportation

(1)Forklift handling requirements

①The total weight of T20 series is about 3500kg, and an appropriate forklift should be selected to transport the machine.

② A commanding officer should be assigned to participate in the handling work to prevent collision and damage to the machine during handling.

(2)Forklift handling process

① First remove the chip box and cooling box of the machine tool;

② Insert the forklift into the two empty spaces under the bed and then lift it up;

③ Lift it up slowly and try to keep the machine tool as balanced as possible to keep the machine in the most stable position.

④ Be gentle when landing to avoid the machine tool hitting the ground. Place level blocks where the machine will be placed.

⑤ Adjust the leveling bolt by dropping it into the recess of the pad. And keep the bolts, nuts and spacers for adjusting the level properly.

Due to the special structure of this machine, it can be placed directly on the ground or in a multi-story factory building with sufficient load-bearing capacity during installation, without laying a foundation. After the machine tool (including 6 shock-absorbing horns) is placed in place, you only need to roughly adjust the level of the machine before use. Unlike traditional machine tools, unreasonable installation will seriously affect the working accuracy and accuracy maintenance of the machine tool.

3 Adjust the level of the machine

(1)Adjust the machine to a preliminary horizontal position, just enough to put the cooling oil tank into it. If the cooling tank cannot be inserted completely, turn the leveling screw to raise the level of the machine.

(2)Adjust the 4 horizontal adjustment bolts to make the horizontal and vertical adjustment within 0.04mm/m [0.0014 in./yd.].

(3)Turn the locking bolt upward until it contacts the bed.

(4)Check the level again.

(5)Remove the spirit level.

(6)Cable to connect feeder.

(7)Check the cooling oil tank behind the machine, and the hoses and cables connecting the oil tank.

(8)Connect the air hose of the pneumatic device.