1. Carry out thorough and proper lubrication of the machine tool according to the lubrication diagram. It is recommended to use the lubricating oil types listed in the following table for lubrication.

(1)Using unsatisfactory lubricants can lead to poor machine performance and failure.

(2)The purity of the lubricating oil used in the machine should be checked frequently.

(3)If the oil is impure, the number of changes should be more frequent than the normal number specified.

(4)Before the machine leaves the factory, the oil tank of the lubrication unit has been emptied. Therefore, after the machine tool is installed, the oil tank should be refueled according to regulations.

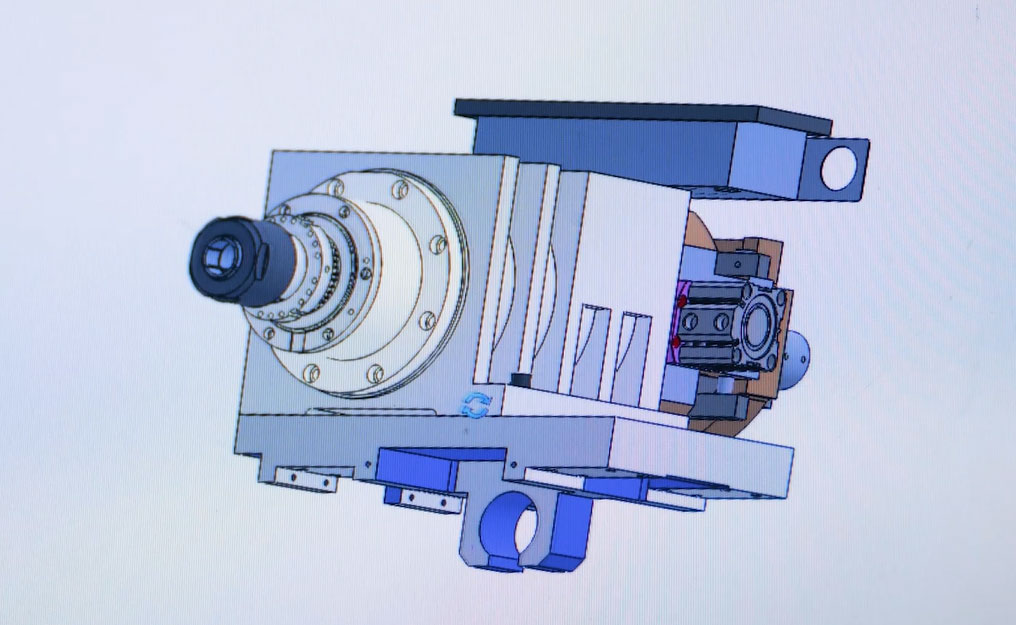

Lubrication unit diagram

|

No. |

Lubrication parts |

Replenish |

Clean and replace |

Recommended oil type |

|

1 |

Lubrication unit |

120 (HR) |

timing |

ISO VG 32 |

2 Main spindle bearing lubrication

Each bearing is equipped with special grade permanent grease, so no oil change is required for a long time. ( The bearing part can only be disassembled by maintenance personnel to avoid affecting its accuracy)

3 Rail lubrication

All guide rails, ball screws, etc. are lubricated by automatic intermittent lubrication pumps. After the machine tool has been running for about 120 hours, the lubricating oil runs out.

|

Recommended lubricants |

ISO VGA 32 |

|

Volume |

2 L |

|

Replacement frequency |

Every 120 hours |

(1)When the lubricating oil height is close to the minimum limit, please fill it with lubricating oil;

(2)If the machine has not been working for a long time, please use the manual button of the oil pump to fully supply oil to the feeding unit before starting the machine.