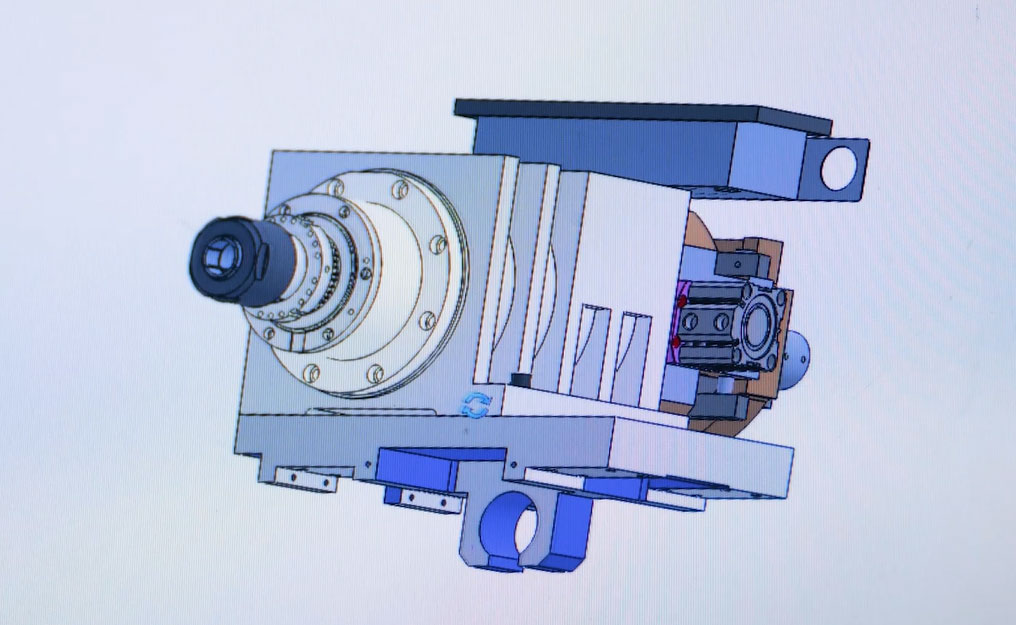

1. Cooling pump

(1)The cooling pump is a separately installed electric pump.

(2)The structure of the cooling pump adopts a mechanical shaft seal and a greased dust cover ball bearing. Therefore, its service life is particularly long.

2 Coolant replacement

|

Recommended type of coolant |

WELCUT B30 (JIS) or similar products |

|

Dosage |

180L |

|

Replacement frequency |

Replace or replenish as needed |

There are two types of coolant that can be used: one that is soluble in water and one that is insoluble in water. It is recommended to use water-insoluble coolant, because water-soluble coolant will cause rust on the surface of the guide rails and other major machine parts.

3. Precautions when using water-soluble coolant

(1) When water-soluble coolant must be used, the following factors must be considered in advance: humidity, corrosiveness, oil separability and stability;

(2) After the operation is completed, be sure to wipe off the coolant on the bed guide rails and the guide rail lights on the bottom plate of the tool holder. Then apply a layer of anti-rust agent;

(3)When the coolant becomes dirty and smells bad, it should be replaced immediately;

(4)When using water-soluble coolant, it is recommended to apply a layer of anti-rust oil to the machined parts. Otherwise, the parts will rust when the coolant dries;

(5)Water-soluble coolant is alkaline and has strong degreasing properties. If the coolant splashes on the skin, it will cause skin inflammation. Therefore, operators should know how to use such coolants;

(6)The dilution method of water-soluble coolant varies depending on the type of coolant. You should follow the coolant manufacturer's instructions for dilution.