Preface

At present, Siemens CNC systems are increasingly widely used in my country's machine tool industry. The standard human-computer interaction interface of the Siemens 840D CNC system is suitable for general-purpose CNC machine tools, but for some special and dedicated machine tools, you need your own dedicated interface. Currently, the OEM (Original Equipment Manufacturer) software design method has become the mainstream method for machine tool interface development. It mainly develops human-machine interfaces through VB (Visual Basic), and uses VC (Microsoft Visual C++) to write language dynamic links associated with Siemens CNC systems. Library, implement interface development through the VB and VC interfaces provided by Siemens CNC system, and embed it into the Siemens CNC system. However, this method requires developers to be familiar with CNC systems and VB and VC programming. OEM software is more expensive, and the OEM interface development cycle is longer. In practical applications, machine tool operators are required to have certain professional knowledge. Therefore, it is very necessary to develop a human-machine interface that is easy to operate, flexible, and intelligent.

1 Brief description of Siemens CNC system interface development method

The main interface development methods of Siemens CNC system are as follows:

(1) Use extended interface to write screen

Utilize and define the blank soft keys on the standard interface to activate the screen configuration file (corn file) stored in the standard cycle directory.

(2) Use the Configuration Package to configure the screen

Based on WinCC Flexible (earlier versions used ProTool/Pro), system variables are accessed through the Configuration Package. Functions that can be implemented include mouse and function key processing, input/output fields, bar bars and historical curves, etc. After installing winCcFlexible on the computer, install the ConfigurationPackage, and finally copy the generated files to MMC (Man-Machine Communication)/PCU (PCUnit) after configuration. Screens generated in this way can be added as extensions to HMIAdvanced (standard interface).

(3) Using the Programming Package to create screens (OEM) allows users to add applications written in VB and VC to HMIA dvanced, and access NC (Numerical Contr01)/PLC (Programmable Logic Controller) variables through the interface provided by the Programming Package to achieve Call multiple screens, manage NC data, realize complex calculations and complex screens, use the interface on the PCU50 (RS232, print port, Ethernet port, etc.) to output processing data and make full use of Windows resources and other functions. By writing a program on the computer, the results (including executable programs, configuration files, etc.) are copied to the MMC/PCU.

Among the above three methods, method (1) is easy to implement, but its function is simple, and the development method for high-end machine tool human-machine interface is far from sufficient. Method (3) is the OEM method, which is very powerful. With the help of VB, VC++ and other software, you can theoretically develop any required interface, but you need to purchase an additional HMI programming package, which is relatively expensive. In addition, you also need VB, VC++ and other software. Support, professional requirements are higher. Method (2) is to use the human-machine interface configured by wjnCC Flexible. It uses graphical editing and has powerful system functions inside. It can quickly configure the screen and shorten the development cycle. Although it also needs to purchase WinCC Flexible software, the price is relatively high. OEM is cheap.

2 WinCC FlexibIe brief introduction

2.1 Introduction to WinCC Flexible

WinCC Flexible series software is a sub-product of Germany's Siemens Industrial Totally Integrated Automation (T-Team). It is an HMI software oriented to machine automation concepts. It has comfortable and efficient design functions. The winCC Flexible series software has open and simple expansion functions, rich system functions and powerful Visual Basic script functions, providing a powerful means for realizing the functions of human-machine interface. WinCC Flexible is powerful yet simple and efficient, easy to use and provides intelligent tools such as graphical navigation and mobile graphical configuration. When creating a project, the basic structure of the HMI project can be generated by clicking the mouse, saving time on interface framework design. WinCC Flexible comes with a rich library that provides a large number of objects for users to use. The WillCC Flexible runtime system is software for process visualization. The runtime system executes projects in process mode to achieve communication with the automation system, visualization of images on the screen and operation of various processes, recording of process values and alarm events. wait.

2.2 Main functions of WinCe Flexible

In the development of human-machine interface, the main functions of winCC Flexible are: the definition of various software on the human-machine interface, the access to various variables and parameters in the NCU (Numerical Control Unit), the access and storage of R parameters and various Access to variables, such as I/O ports, data block DB, etc., as well as file management in NCU and file management in MMC.

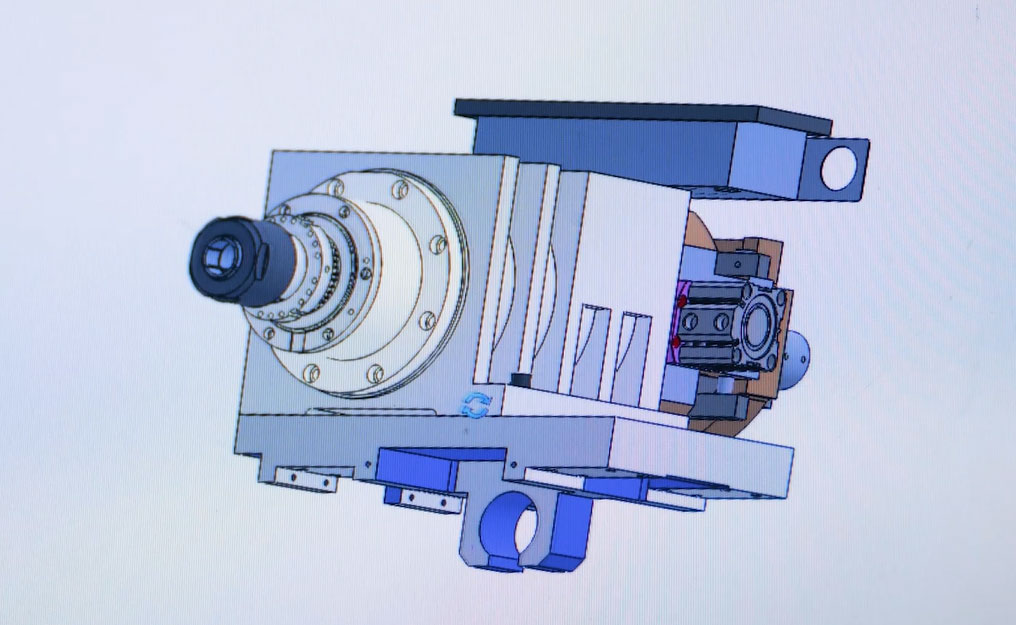

3Dedicated CNC grinder human-machine interface design

Taking a company's special grinder as an example, we will introduce the process of developing human-machine interface using WinCC Flexible. According to the actual needs of machine tools, a process-oriented guided Chinese human-machine interface is developed. Install the winCC Flexible development software on a personal computer. Under the WINDOWS operating system, you can access NCK (Numerical Control Kemel), PLC, MMCl03 variables and files through the Configuration Package interface provided by winCC Flexible.

3.1 Overall design idea

The user interface design developed by WinCC Flexible is not only the appearance design of the form itself, but also the editing of the underlying internal scripts and the overall structure, which guides machine tool operators to operate through a reasonable humanized structure. How to process and store data and manage files through scripts? The process database management software developed using the VBS (Visual Basic Script) script provided by WinCC Flexible can process workpiece data, grinding wheel data, dressing data, etc. for axle grinding. The cutting process parameters are stored and managed, and the processing data is ultimately stored in the form of CVS (data file format) data stream files. The overall design idea is shown in Figure 1.

3.2 Configure the system

Before the machine tool runs the developed human-machine interface program, the Siemens WinCC Flexible runtime operating environment needs to be installed on the Siemens 840D CNC system. In addition, the regie.ini file needs to be configured. The configuration instructions are as follows:

[HSoftkeyTexts]HSK6=“WmCC Flexible” (Configuration level 6 software is renamed WmCCFlexible, press this key to enter the developed human-machine interface);

Task6---name:=OEMframe,Cmdline:="E:\\LProgram

Files\\Siemens\\SIMATICWinCCFlexible\\WinCCFlexible

2008Runtime\\I-ImiRtm.exef:\kAdd_On\\CZ.fwx”. (Configuring the path of the human-machine interface)

3.3 Guided structural design

How to reflect the machining process sequence in the human-machine interface to make machine tool operation simple, easy to understand and easy to use is the core issue of guided interface design. Taking the workpiece processing as the main line and following the grinding process sequence, the human-machine interface screen configuration is performed. The interface is divided into several modules such as workpiece setting, equipment management, grinding wheel dressing, and file management, as shown in Figure 2.

The workpiece settings include the basic information of the workpiece, the selection of grinding methods and the settings of pre-processing parameters such as grinding parameters; the grinding wheel dressing module includes dressing-related parameters. The operator follows the prompts in the table below on the interface and completes the setting of relevant parameters in order to start processing. The operation is simple, fast and efficient.

以Multi-step parts processing is an example. According to the multi-machine processing process shown in Figure 3, first enter the processing parameter preset interface, as shown in Figure 4. After entering the workpiece name, set the basic information of the workpiece, process step selection and The grinding parameters on the left are shown in Figure 5, Figure 6, and Figure 7. After completing the input of an interface parameter, click the save button, and the display status of the interface on the initial interface will change from pending setting to setting completed, prompting the operator that the setting has been completed.

3.4 Modular data management

The system adopts a modular programming method, which not only facilitates various combinations and modifications of system functions, but also facilitates supplementation and maintenance by technical maintenance personnel who are not involved in the development. On the basis of the system function analysis, according to the programming characteristics of Siemens 840D CNC system and WinCC Flexible configuration software, the system function module structure is established, as shown in Figure 8. The workpiece name, grinding wheel number, and dresser number are used as the index marks of each sub-database.

Data management is indexed by workpiece name, and VBSript programming is used to implement management operations such as creating, deleting, and renaming files, and reading and storing processing data, as shown in Figure 9。

he main code of the "New" function is as follows:

DoWhilek

k=SmartTags(“sortA)osti”)(i)

Ifk=0Then

SmartTags(“sort_numb”=i

SmartTags(“sort_posti”)(i)=1

EndIf

i=i+l

Loop

SelectCaseSmartTags(“sort_numb”)

CaselSmartTags(“FileNamel”)=

SmartTags(“NEw—FileName”)

Case2SmartTags(“FileName2”)=

SmartTags(“NEW_FileName”)

......

EndSelect

4 Conclusion

The human-machine interface developed using the WinCC Flexible series software was applied to a special grinder, and the workpiece grinding test was conducted. The guided operation interface, humanized interface design and convenient and efficient data management achieve the expected design goals. In the future, with in-depth research on the structure and hardware of CNC systems, machine tool manufacturing companies need to add more reliable and professional functions to CNC machine tools through secondary development of HMI interfaces, and develop more comprehensive and professional CNC machine tools. Human-machine interface with more flexible and convenient operation.