The half-year inspection is mainly for consumables that are easily overlooked and do not need to be replaced frequently. Do not ignore these inspection items, otherwise the machine may suffer serious malfunctions.

⑴ Half-year inspection items

|

Check unit |

No |

Checkpoints |

Description |

Remark |

|

|||

|

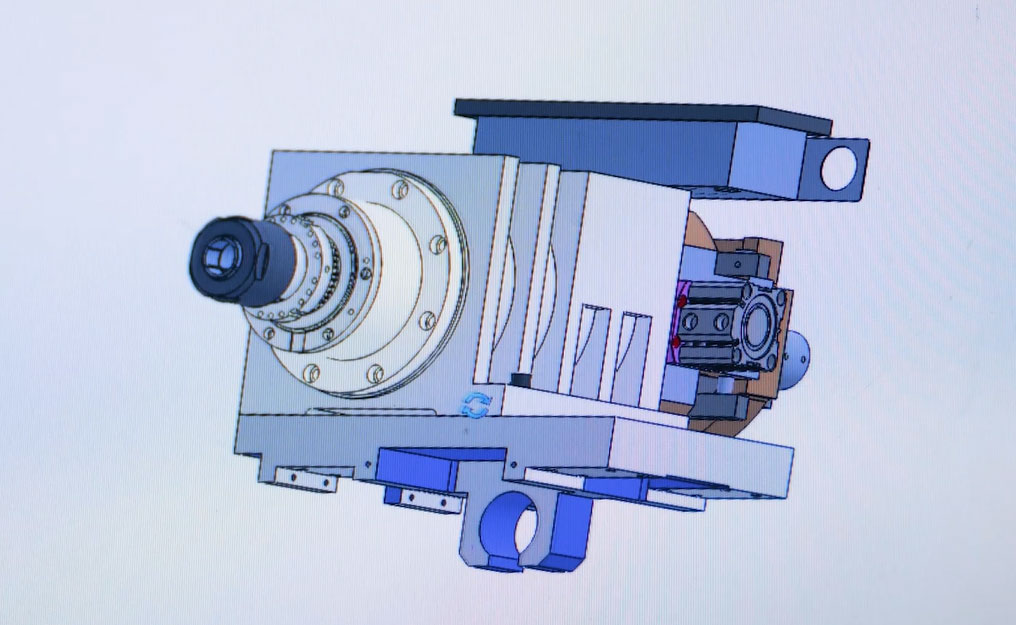

Spindle |

① |

Accuracy changes |

Check its inner diameter size with the dial indicator |

If the deviation is abnormal, Check and compare with the machine report. |

|

|||

|

② |

Bearing ring wear |

Visually and by touch |

Replace worn bearings |

|

||||

|

Lubricating oil pump |

3 |

Flow Switch |

Clear the oil from the fuel tank |

Check if the float (white) is working properly |

|

|||

|

Device |

Item |

Content |

Remark |

|||||

|

Spindle |

Temperature |

Check it after the spindle rotates at 3000 rpm for 30 minutes. |

Touch the position of the spindle bearing chamber with your hand. Generally, the temperature is not high. |

|||||

|

Feed unit |

Screw lubricant |

Visual inspection |

Keep clean and well greased |

|||||

|

Guide |

Visual inspection |

Keep clean Check the condition of the oil |

||||||

|

Bushing |

The carbide part inside the guide bush |

Visual inspection |

No scratch marks and no burrs |

|||||

|

Cooling unit |

Chip pile in cutting tank |

Check if chips have piled up |

Clean up chips |

|||||

|

Lubricating oil |

flow |

Check fuel consumption per hour |

4.0cc/15min, 2,000cc/120hours. |

|||||

|

oil leak |

Visually inspect each pipeline |

Retighten loose parts |

||||||

|

Control box |

Cooling fan cover |

Visually and by touch |

Clean the filter with neutral paper |

|||||

|

Clamp unit |

Lubricating grease for sliding parts |

Visual inspection |

If necessary, add grease |

|||||

|

Spindle drive |

Synchronize belt |

Visually and by touch |

If worn, replace one |

|||||