Modeling and simulation of dynamic characteristic parameters of joint surface of CNC machine tools based on neural network

Since there are joint surfaces between machine tool components, the "flexible" nature of the joint surfaces that both stores and consumes energy greatly affects the static and dynamic characteristics of the entire machine tool. The stiffness and damping between the combined surfaces, especially the damping, are often greater than the elasticity and damping of the structure itself. At present, the difference between the analytical value and the experimental value of the complete machine tool characteristics is about 50%. Therefore, studying and mastering the dynamic characteristic parameters of the joint surface will provide the necessary theoretical basis for the dynamic optimization design of machine tool structures and even various mechanical structures. Research shows that there are many factors that affect the dynamic characteristic parameters (stiffness, damping) of the joint surface, including joint surface materials, joint surface processing methods, joint surface processing quality, the medium between the joint surfaces, the surface pressure of the joint surface, etc. Most of the factors The influence laws are all non-linear, and there is mutual influence between various factors. The theoretical calculation method is aimed at various typical joint surfaces in mechanical structures. Through theoretical analysis and dynamic testing, the dynamic basic characteristic parameters of the joint surface—stiffness and damping—are obtained, and the calculation expressions of the corresponding basic characteristic parameters are established. However, the disadvantages of this method are: there are too many factors that affect the characteristic parameters of the joint surface, it requires a large amount of data accumulation, and it is also restricted by the conditions for using the formula. It can only be used when specific conditions are met. Therefore, before the interaction mechanism of the joint surface is truly revealed, it is still very difficult to accurately obtain the theoretical expressions of the characteristic parameters of the joint surface in theory.

The proposal and development of artificial neural network theory has provided us with a powerful tool with good nonlinear mapping capabilities. Compared with traditional data processing methods, it is more suitable for dealing with fuzzy, nonlinear and other obscure problems. The basic parameters of the dynamic characteristics of the fixed joint surface are affected by many factors, and many factors are nonlinear and fuzzy, so artificial neural networks are suitable for use. This paper uses artificial neural network method to study the dynamic parameters of the joint surface, and establishes a prediction model for the dynamic characteristic parameters of the joint surface.

1 Modeling of dynamic characteristics of joint surfaces

1.1 Analysis of modeling process

Commonly used types of neural networks include linear neural networks, BP neural networks, Hopfield networks, etc. BP neural network (Back-Propagation Network) is a multi-layer network that performs weight training on nonlinear differentiable functions. BP network contains the most essential part of neural network theory. Due to its simple structure and strong plasticity, it has been widely used. Therefore, this article uses BP neural network.

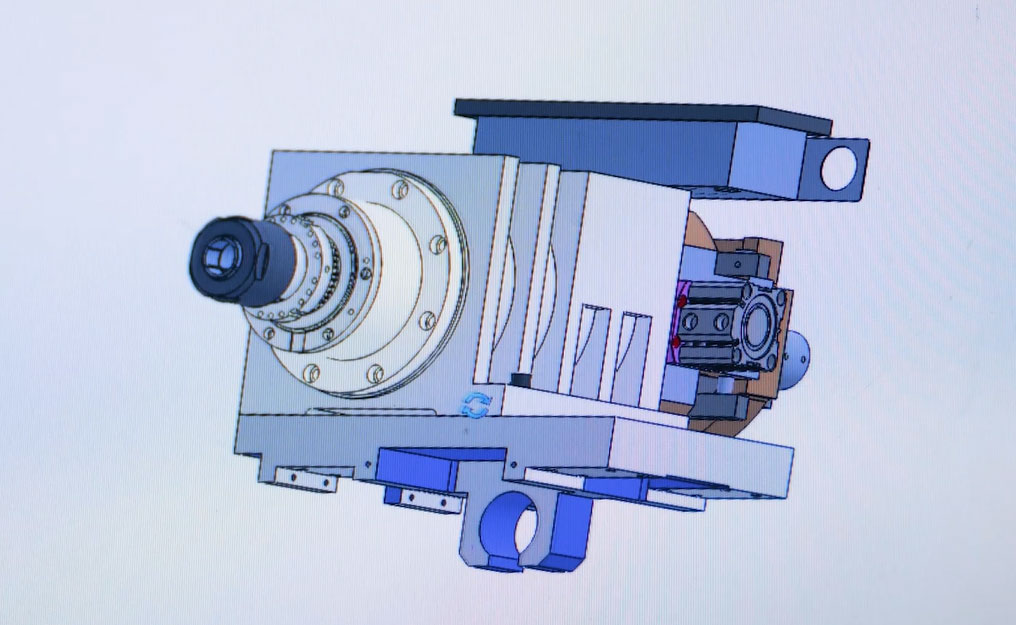

In the process of modeling the dynamic characteristics of the joint surface, a 3-layer BP neural network is used to complete the mapping of the functional relationship of the joint surface characteristic parameters, and the factors that have obvious influence on the dynamic characteristics of the joint surface are selected as input layer vectors. The input layer training parameters selected accordingly are respectively There are 5 layers of input including surface material, roughness, joint surface torque and medium. The input layer parameters are represented by vectors as

X = (x1, x2, x3, x4, x5)

The output layer uses two neurons, corresponding to the tangential stiffness and tangential damping of the fixed joint surface. The hidden layer uses 12 neurons, and the neurons between each layer are fully connected, while there is no connection between the neurons in each layer. Each neuron uses Sigmoid as the activation function. The model structure is shown in Figure 1.

Common BP algorithms include gradient descent method and quasi-Newton method. Although the gradient descent method provides a simple and effective method for training networks, when solving practical problems, the convergence rate is often too slow, which affects the quality of the solution. Although the quasi-Newton method converges faster than the gradient descent method, its calculation is more complicated. The standard BP network algorithm has the characteristics of clear thinking, rigorous structure, and strong operability, and a 3-layer BP network can complete any mapping from n dimensions to m dimensions. However, there are the following two defects in its convergence process: ① Convergence The speed is slow; ② There is the so-called "local minimum" problem.

The Levenberg-Marquardt (LM) method used in this article is actually a combination of the gradient descent method and the Newton method. It has fewer iterations, fast convergence speed, and high accuracy, and can overcome the defects caused by the standard BP network. The network is learned using the BP algorithm of Lm approximation. The algorithm steps are as follows:

(1) Give the training error allowable value ε, coefficients μ0, β, and initialization weight and threshold vector X(0), and let k = 0, μ = μ0;

(2) Calculate the network output and error index function E(x(k));

(3) Calculate the Jacobi matrix J(W) and calculate ΔW according to equation (1)

The new weight vector can be obtained according to the following rules:

For the Gauss-Newton method, the learning rule is

Since the Lm algorithm is an improvement on the Gauss-Newton method, its learning rule is

In the formula:

μ is the Billy factor;

e(W) is the error vector;

I is the unit square matrix.

(4) If E(W(k))<ε, go to step (6); otherwise, calculate W(k + 1) using equation (1) and calculate the error index E(W(k + 1));

(5) If E(W(k + 1)) < E(W(k)), then k = k + 1, μ = μ/β, go to step (2); otherwise μ = μβ, go to step (3) );

(6) The iteration ends.

1.2 Selection of training sample data

In order to obtain learning sample data, a combination of Q235, 45 steel, HT200, HT250, and HT300 materials was selected. The roughness varied from 0.8 to 6.4 μm in sequence, and 7 sets of torque changes were performed. The joint surface dynamic characteristics test was conducted in different media. A total of Obtain 300 sets of training data. Considering that the BP network requires input data to be between 0 and 1, the selected training parameters must be normalized. The normalization method is as follows:

In the formula:

x and y are the results after normalization;

a and b are the minimum and maximum values of the data.

For surface pressure and roughness, the surface pressure and roughness are normalized using their respective maximum and minimum values. For media and materials, this article artificially normalizes them, as shown in Tables 1 and 2.

2 Network training and experimental verification

The process of training a neural network is actually a function approximation process, which is a process of continuously modifying the connection weights of the interactions between neurons within the neural network. Set the error allowable value to 0. 0001, u = 0. 01, initialize the network weight vector W, take 90% of the 300 sets of training data obtained in the above experiment as training network samples, and 10% of the data as test samples. After the training error reaches the error control accuracy, the comparison between the network output of the training sample and the experimental values of the dynamic characteristic parameters of the joint surface is shown in Figures 2 and 3. The straight line in the figure is the combination line where the predicted value and the actual value are completely equal. From the figure, it can be It can be seen that the data points are distributed on or near the best combination line, so it shows that the network topology used in this article is appropriate.

Select 1 set from 60 sets of test data, and use the trained joint surface dynamic characteristics neural network model to simulate in the joint state shown in Table 3. The comparative changes between the test values and simulation values of the joint surface dynamic characteristics parameters are shown in Figure 4. 5. See Table 3 and Table 4 for simulation errors. From the figure, we can see that the experimental values and simulation values of the dynamic characteristic parameters of the joint surface are in good agreement in terms of magnitude and change trend, and the relative errors are mostly within 10%.

3 Simulation results analysis

It can be seen from the comparative changes of the above-mentioned sets of experimental values and simulation values of the dynamic parameters of the joint surface that the prediction model of the dynamic characteristic parameters of the joint surface established using the BP neural network method can train the neural network based on the actual joint surface status data provided, thereby The corresponding optimal neural network connection weights for the actual joint surface state are provided. After simulation, the dynamic characteristic parameters of the joint surface that conform to the actual joint surface state can be obtained. The BP neural network method in this article is a modeling method that combines surface dynamic characteristic parameters with good general form and overcomes the shortcomings of traditional theoretical analytical modeling difficulties.

4 Conclusion

Neural network technology was applied to the study of the dynamic characteristics of the joint surface, and a BP neural network model was established to predict the dynamic characteristics parameters of the joint surface. This model takes into account various factors that affect the dynamic characteristic parameters of the joint surface, and overcomes the shortcomings of the nonlinear programming method in identifying the dynamic characteristic parameters of the joint surface, which is difficult to ensure the stability and convergence of the identification algorithm. Influences such as bonding surface material, medium and roughness can be mapped to the prediction of bonding surface dynamic characteristic parameters of the actual bonding state through network structure parameters. The actual verification and comparison results also show that it is feasible to use the BP neural network method to model and simulate the dynamic characteristic parameters of the joint surface.