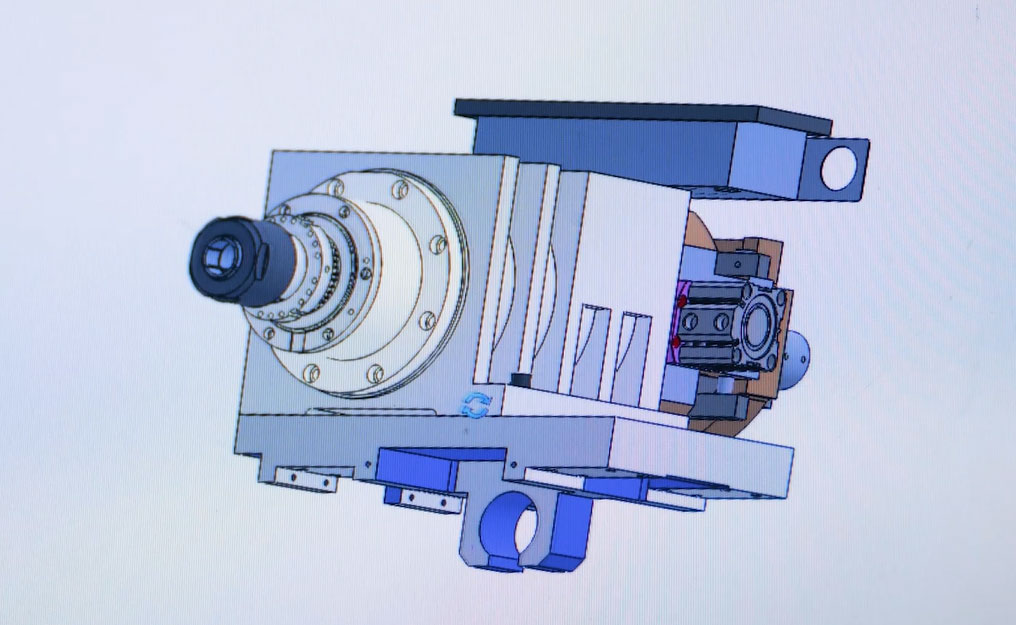

The CNC machine tool spindle system includes components such as spindle, bearings, tool holders, tools (or workpieces), etc., and is an important subsystem of CNC machine tools. The dynamic characteristics of the spindle system directly affect the machining accuracy, surface roughness and productivity of the workpiece. Therefore, the dynamic design and analysis of the spindle system has attracted widespread attention from the business community and scholars. In particular, in recent years, the demand for high-end CNC machine tools characterized by high-speed processing has been increasing day by day, so the dynamic design of the spindle system has become even more important. Good spindle system dynamic performance is mainly reflected in high stiffness, low vibration, low deformation, and low noise. Low, that is, it has superior ability to resist forced vibration and self-excited vibration. At present, the overall performance of my country's domestically produced high-end CNC machine tools still lags behind that of developed countries. The poor dynamic performance of the spindle system is an important reason. Therefore, how to improve the dynamic performance of the spindle components has become an important research issue in the machine tool manufacturing industry.

1. Key issues on dynamic characteristics and future research trends

Parameters that characterize the dynamic characteristics of the spindle system The dynamic characteristics of the spindle system is a broad concept, which generally refers to all performance indicators related to the vibration resistance and stability of the spindle system.

2. Analysis method of spindle system dynamic characteristics The main content of spindle system dynamics analysis

Create a dynamic model of the spindle system; analyze and determine various parameters that characterize the dynamic performance of the spindle system; evaluate and predict the dynamic performance of the spindle system; design and adjust various factors that affect the dynamic performance of the spindle system, that is, implement optimal design . For a long time, scholars have proposed a variety of dynamic analysis methods around the spindle system of CNC machine tools in their continuous exploration and practice. It mainly includes finite element method, transfer matrix method, impedance coupling method, experimental analysis method, etc.

2.1 Finite element analysis method of spindle system dynamic characteristics

The finite element analysis method can be used to perform static analysis on the spindle system to obtain the static stiffness, and dynamic analysis to obtain the natural frequency, dynamic response, and implement optimal design. In the study of spindle system dynamics analysis, the finite element method is the most commonly used method. Common engineering software includes AN SYS, ANSYS/Workbench, MSC.NASTRAN, ABAQUS, MSC.MARC\LMSVirtua.lLab, etc. The finite element method is easy to apply and has high solution accuracy, but it also has shortcomings when performing dynamic analysis of the spindle system. Finite element software cannot be well combined with bearing analysis theory to analyze the spindle bearing system. In order to perform the analysis effectively, the generalized load corresponding to the bearing load must be calculated through integration, and the relationship between the bearing load and deformation must be linearized. This operation reduces the accuracy of the analysis.

2.2 Transfer matrix of dynamic characteristics of spindle system

The analytical transfer matrix method is a classic method for analyzing the dynamic characteristics of slender structures such as shafts and beams. The basic idea of applying the transfer matrix method to conduct dynamic analysis of the spindle system is: first, discretize the spindle system, and the system becomes a discrete body composed of several concentrated masses, rigid disks and elastic shaft segments (the segmentation point is often taken at There are significant changes in the wheel disc, bearing, coupling and shaft diameter); then, obtain the transfer matrix of each unit (the combination of wheel disc and shaft spring); finally, through the unit transfer matrix, transfer each unit from left to right The state vectors at both ends of the shaft segment are connected. According to the boundary conditions of the main shaft, the frequency polynomial is obtained, and the critical speed and dynamic response of the rotor system are obtained using the iterative method.

2.3 Impedance coupling substructure analysis method of spindle system dynamic characteristics

The basic idea of the impedance coupling substructure analysis method is: taking the assembly composed of the spindle tool holder and the tool as the research object, the spindle system is divided into several substructures; each substructure is subjected to the finite element method or related beam theory to obtain the substructure. The frequency response function of the end points of the structure; using balance and compatibility conditions, each substructure is coupled, and finally the frequency response function matrix of the entire assembly is established.

3. Dynamic characteristics of spindle bearings

In order to introduce bearing dynamic characteristics into the spindle system dynamics analysis, traditionally, the bearing is usually equivalent to linear spring damping. This is an approximately equivalent method and does not truly reflect the dynamic performance of the bearing. Especially for high-speed machining spindle systems, this approximately equivalent method often brings large analysis errors. The bearings of high-speed spindle systems are generally angular contact ball bearings. The position of the bearing, the direction of the bearing, the combination of bearings (single group, two groups or several groups forming a single point support) or the type of bearing preload force all affect the dynamic performance of the bearing system. Therefore, it is necessary to refine the dynamic model of the bearing structure in order to truly reflect the dynamic performance of the spindle system.

4. Development trends in research on spindle system dynamic characteristics

As the requirements for CNC machine tool processing accuracy and processing efficiency become higher and higher, the research on the dynamic characteristics of the machine tool spindle system becomes more and more important, reflecting the following characteristics:

(1) Emphasis on accurate modeling of the spindle system to improve the prediction accuracy of dynamic characteristics. From the research trend, this is reflected in the following three aspects: First, consider the coupling effect of multi-field environments to model the spindle system, for example, Conduct modeling research considering the coupling effect of the spindle system's inertial force field and thermal field [; the second is to strengthen the modeling and parameter identification research of the spindle bearing system and other joint surfaces and introduce nonlinear factors) to improve the accuracy of the spindle system dynamics analysis. Accuracy; the third is to comprehensively consider factors affecting the dynamic characteristics of the spindle system, such as rotational inertia, gyroscopic moment, shear deformation, axial force and internal damping, etc., and conduct comprehensive modeling research on the dynamics of the spindle system.

(2) Combine the optimization theory with the spindle system dynamics analysis and design. The theories that can be used for spindle system dynamics optimization include topology optimization and parameter optimization. Topology optimization is to obtain the best arrangement of structural parts, such as the determination of bearing span moments; parameter optimization is to obtain the best geometric and physical parameters of the spindle system. The ultimate goal of spindle system dynamics analysis includes the prediction and optimization of dynamic performance. Therefore, spindle system dynamics analysis and design combined with optimization theory is an important development trend in spindle system dynamics research.

(3) Dynamic analysis of the spindle system in the operating state. The inherent dynamic characteristics of the spindle system in the stationary state and the spindle system in the high-speed operating state are different. However, at present, most scholars conduct research on the assumption that the two are equal, that is, using the dynamic performance obtained by static testing and the performance of the simulated operating state, which is effective for low-speed spindle systems (<10000rpm). For high-speed spindle systems, the analysis error is large. For high-speed machining spindle systems, the stiffness of the bearings will decrease as the rotational speed increases, showing nonlinear characteristics of variable stiffness. Therefore, in order to accurately analyze the dynamic performance of the spindle system, there is a tendency to test and analyze the dynamic performance of the spindle system under operating conditions.

5. Conclusion

This article conducts a review and research on the dynamic analysis methods of CNC machine tool spindle system. The main contents include:

(1) Introduction to characterizing spindle system dynamics

(2) Analyze according to two working conditions respectively. The deformation of working condition 1 is larger than that of working condition 2, which has a greater impact on the column and should be taken into consideration;

(3) The natural frequency and mode shape of the column in the constrained state have changed significantly compared with those in the unconstrained state. The low-order frequency under restraint is significantly reduced, and the low-order vibration mode changes from the bending vibration mode in the unconstrained state to the swing with the restraint surface as the fulcrum;

(4) Structure A has the best stiffness, followed by structure C. In addition, we see that simply increasing the number of plates and changing the form of individual plates cannot improve structural performance. This provides the necessary theoretical basis for future machine tool plate reinforcement design.