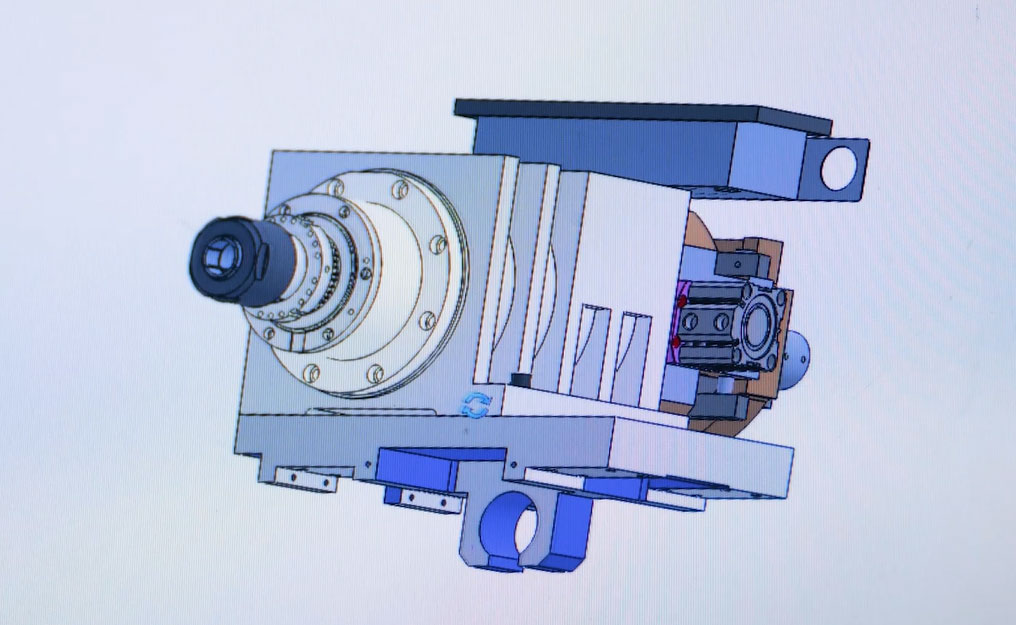

The CNC control system is an important part of the high-speed machining center, which determines the speed, precision and surface quality of the machine tool to a large extent. Therefore, for high-speed machine tools that process free-form surfaces of molds, the performance of the numerical control system is particularly important.

When processing high-precision free-form surfaces, the tool path composed of micro-segments of straight lines and arcs creates a huge part program. These data flows need to be stored and processed by the machine tool control system. Therefore, the length of the program segment processing time is a decisive factor in the CNC control system. An important indicator of work efficiency. At present, the program segment processing time of high-end CNC control systems can generally reach 0.5ms, while the program segment processing time of individual CNC systems has been shortened to 0.2~0.4ms.

Applications, and can work with nanometer resolution, in order to obtain high machining accuracy and surface quality in the case of high-speed machining.

At present, high-end CNC systems can also be connected to CAD/CAM systems from different manufacturers. Data is transmitted from the CAD/CAM system to the control system at a very high speed via Ethernet. The integration of CAD/CAM into the control system can achieve good results in processing complex contours of molds to a large extent, and makes a very important contribution to shortening adjustment time and programming time. Modern CNC numerical control systems for high-speed machining of molds, in addition to having a short program processing time necessary to ensure high-speed feed speeds, should also have Nurbs and spline interpolation functions.