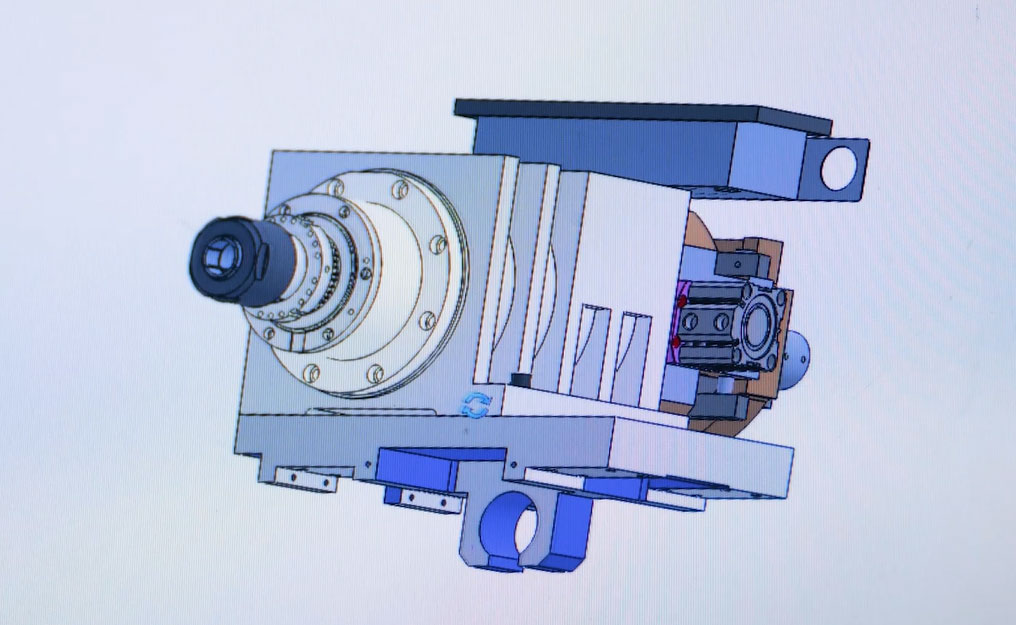

The CNC turning and milling machine tool is a very precise production and processing tool. Compared with ordinary lathes, it has absolute advantages in terms of accuracy, efficiency, and qualification rate. Compared with ordinary lathes, turning and milling composite machine tools can greatly improve product quality and production efficiency, improve the competitiveness of enterprises, and promote development.

Turning and milling compound machine tools: rely on the drive motor to drive the ball screw transmission. The ball screw has interference after being pre-stretched and installed, and the transmission has no gap. The accuracy is mainly guaranteed by the machine tool itself and the program. During the machining process, the position can be measured by the encoder, which can compensate for errors caused by tool wear and other reasons. Therefore, CNC turning and milling composite machine tools have good processing quality and stable precision.

High efficiency: effectively reduces production preparation time and improves machine tool utilization; reduces costs: dual spindles can work at the same time, reducing the number of machine tools, making it easier to plan production and saving investment costs and workshop area. It is precisely because the turn-milling compound machine tool has so many advantages, and more importantly, these advantages are in line with the modern metal processing industry's demand for high-efficiency, high-profit, and low-cost processing methods.

That’s it for the above introduction about turning and milling compound machine tools. I hope it will be helpful to your understanding.