Our country is a newly emerging modern manufacturing country. In recent years, the country has attached great importance to the research and development of high-speed cutting technology for superhard tools. Industrial materials represented by high-temperature alloys, titanium alloys, stainless steel, isostatic graphite, silicon materials, sapphire, ultra-high-strength steel, and high-temperature structural ceramics are difficult to process and costly, and they also require higher requirements for supporting processing tools. Require. Therefore, superhard cutting tools have become the preferred material in industrial upgrading.

Our country is a newly emerging modern manufacturing country. In recent years, the country has attached great importance to the research and development of high-speed cutting technology for superhard tools. Industrial materials represented by high-temperature alloys, titanium alloys, stainless steel, isostatic graphite, silicon materials, sapphire, ultra-high-strength steel, and high-temperature structural ceramics are difficult to process and costly, and they also require higher requirements for supporting processing tools. Require. Therefore, superhard cutting tools have become the preferred material in industrial upgrading.

The national "863" plan and key science and technology projects are included in the development and application of superhard cutting tools. After the 13th Five-Year Plan, my country's manufacturing industry has entered a period of transformation and upgrading.

Based on the statistics, surveys and analyzes of the Tool Branch of the China Machine Tool Industry Association, the total scale of my country's tool market consumption, import and export were calculated. The total consumption scale of my country's tool market increased from 38.8 billion yuan in 2017 to 42.1 billion yuan in 2018, a year-on-year increase of 8.5%

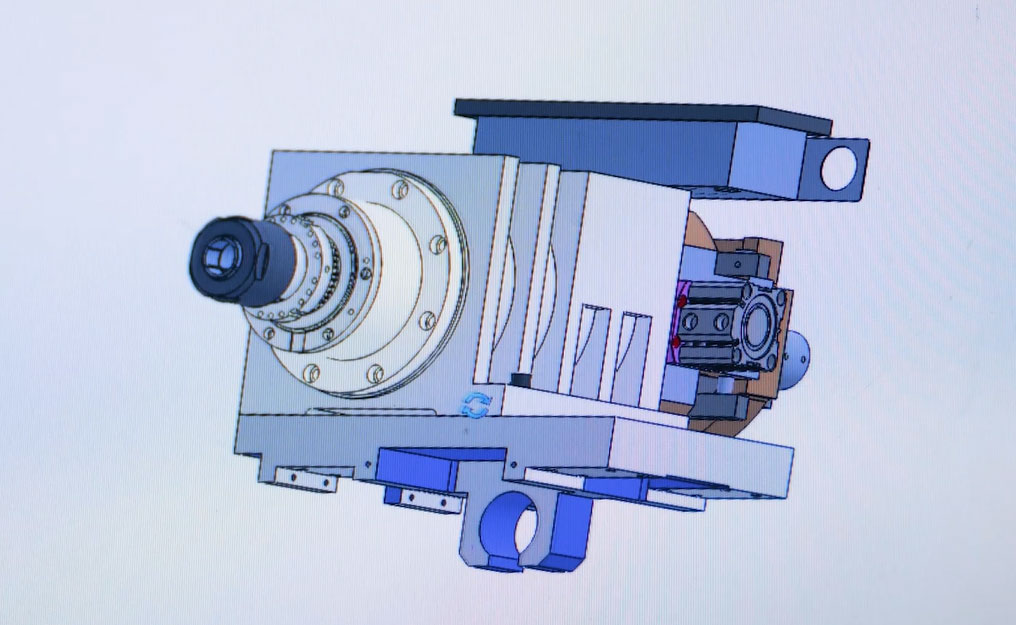

At present, modern manufacturing tools are making great strides in the direction of "high speed, precision, composite, intelligence and environmental protection". In the car manufacturing industry, a large number of "high-precision, high-efficiency, high-reliability and specialization" super-hard cutting tools have been used to replace traditional standard cutting tools, and production efficiency has been greatly improved.

In the ever-changing electronic product manufacturing industry, such as processing 3C products such as mobile phones and tablet computers, the successful introduction of "high-precision, high-speed, high-stability super-hard tools" has doubled the processing efficiency and improved product quality stability. It has been greatly improved and the processing quality has been significantly improved without increasing the processing cost.

However, the performance of domestically produced cutting tools is still difficult to meet its requirements, so they have to rely on imports. Therefore, it is very necessary and urgent to develop domestic superhard tools.