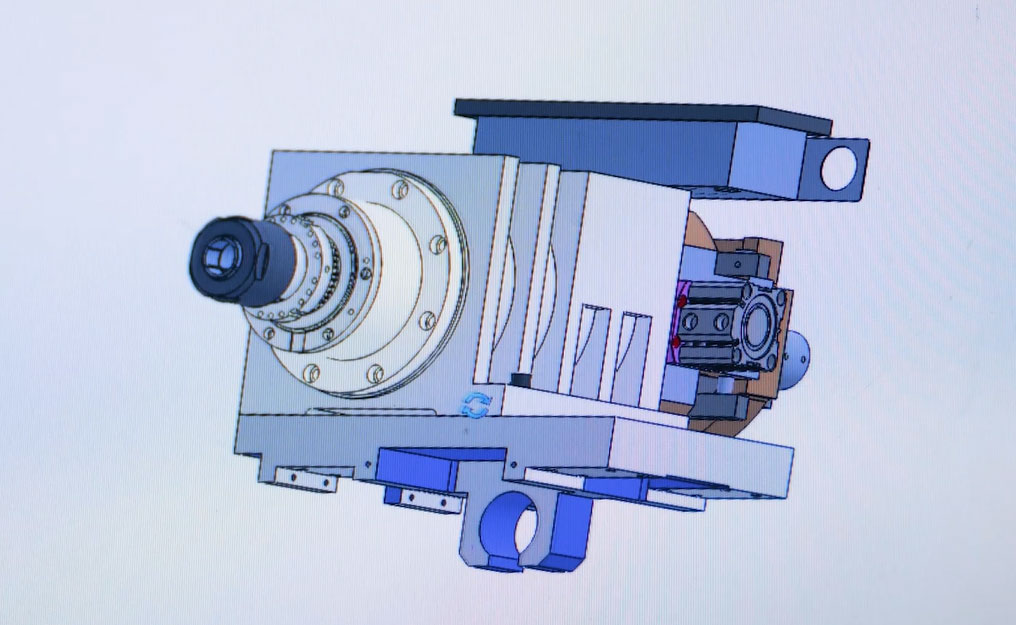

The rail usually refers to the rolling guide rail, and this type of element is often called "linear guide rail". The linear guide itself is divided into two parts: the slide rail and the slider. There are internal circulating balls or rollers in the slide block, and the length of the slide rail can be customized. It is a modular component, which is a standardized and serialized unique product produced by a special manufacturer. It can be installed on the machine tool, and can be disassembled and replaced after wear and tear. Linear rails use rolling friction, are fast, have low resistance, and are easy to lubricate. Nowadays, more and more linear rails are used in the machine tool industry. The line rail is currently used on the CNC lathe with small friction, the machine tool responds quickly, and the inertia is small. Generally, it is fixed on the bed through multiple sets of pressure plates, which is convenient for installation and adjustment.

Our line-rail CNC lathe mechatronics planning has the advantages of beautiful appearance, reasonable structure, wide range of uses, convenient operation, one person with multiple machines, etc.; spring chuck is used for clamping, convenient loading and unloading of workpieces, and accurate positioning; or three-grip chuck Clamping, the application range of the machine tool is wider; the main shaft adopts high-precision spindle unit to rotate, and the carriage adopts high-precision ball rod transmission in the vertical and horizontal directions; the guide rail adopts linear guide rail movement, which can ensure the machining accuracy and working life of the machine tool stably for a long time. And it can realize the automatic cutting of outer circle, end face, inner hole, grooving, arbitrary conical surface, spherical surface and various metric, imperial and American threads of various products, and is equipped with perfect S\T\M functions, which can be released And receive a variety of signals to actively control the processing program. This machine tool can be widely used in batch finishing of valves, plumbing, auto parts and other hardware parts.