How CNC Swiss Type Lathes Revolutionize Modern Manufacturing

1. Introduction

In the world of manufacturing, precision is paramount. CNC Swiss Type Lathes have emerged as a critical tool in achieving unparalleled accuracy and efficiency. These machines utilize Computer Numerical Control (CNC) technology to automate and streamline the machining process, transforming how components are produced across various industries. By understanding the fundamentals of CNC Swiss Type Lathes, we can appreciate their significance in modern manufacturing.

2. Understanding the Mechanics of CNC Swiss Lathes

CNC Swiss Type Lathes operate on a unique principle that differentiates them from traditional lathes. The essence of their design lies in a sliding headstock that enables the workpiece to be fed through the spindle, allowing for a variety of complex machining operations without moving the part. This design is particularly beneficial for producing small, intricate parts with tight tolerances.

At the heart of the CNC Swiss Type Lathe is its ability to perform multiple functions, including turning, drilling, and milling, all in one setup. This capability not only saves time but also increases the overall efficiency of the manufacturing process.

3. Key Advantages of CNC Swiss Type Lathes in Manufacturing

The adoption of CNC Swiss Type Lathes in manufacturing brings numerous advantages that can significantly enhance productivity and quality.

3.1 Enhanced Precision and Accuracy

CNC Swiss Type Lathes are renowned for their precision. With advanced programming capabilities, these machines can achieve tolerances as tight as 0.0005 inches. This level of accuracy is critical in industries where even the slightest deviation can lead to significant failures.

3.2 Increased Production Efficiency

The automated nature of CNC Swiss Type Lathes allows for continuous operation, reducing downtime and increasing throughput. With the ability to run multiple parts simultaneously, manufacturers can meet high demand without compromising on quality.

3.3 Reduced Setup Times

One of the standout features of CNC Swiss Type Lathes is their quick setup times. Unlike traditional lathes, which often require extensive adjustments for different jobs, CNC Swiss Lathes can switch between tasks with minimal intervention. This agility leads to faster turnaround times and greater flexibility in production schedules.

4. Applications of CNC Swiss Type Lathes in Various Industries

CNC Swiss Type Lathes have found applications across a wide range of industries, each benefiting from the unique capabilities these machines offer.

4.1 Aerospace Manufacturing

In aerospace manufacturing, precision and reliability are non-negotiable. CNC Swiss Type Lathes are used to produce complex components like brackets, fittings, and valve bodies that must meet stringent safety and performance standards.

4.2 Medical Device Production

The medical field demands components that are not only precise but also manufactured with cleanroom standards. CNC Swiss Lathes are instrumental in creating intricate parts for surgical instruments and implants, ensuring they meet the rigorous specifications required in healthcare.

4.3 Automotive Parts Fabrication

The automotive industry leverages CNC Swiss Type Lathes to produce high-volume parts such as fasteners, bolts, and bushings. The ability to maintain tight tolerances and repeatability is crucial in this fast-paced sector, where quality control is paramount.

5. The Evolution of CNC Swiss Type Lathes

The technology behind CNC Swiss Type Lathes has evolved significantly over the years. Initially developed in Switzerland in the late 19th century, these lathes have undergone numerous enhancements, including the integration of advanced software and controls.

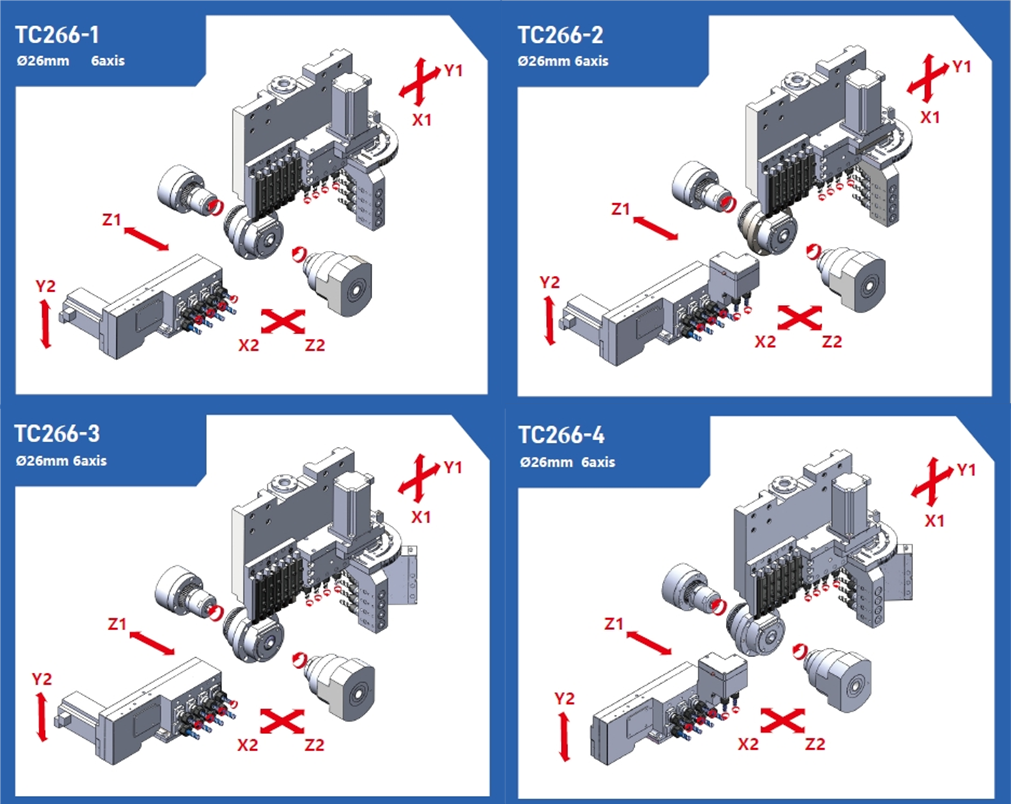

Modern CNC Swiss Type Lathes now feature multi-axis capabilities, allowing for even more complex geometries to be machined efficiently. The continuous innovation in tooling and materials also contributes to their growing popularity in the manufacturing landscape.

6. Selecting the Right CNC Swiss Type Lathe for Your Needs

Choosing the right CNC Swiss Type Lathe can be a daunting task, given the variety of options available. It's essential to evaluate your specific manufacturing requirements to ensure you select the most suitable machine.

6.1 Factors to Consider

When selecting a CNC Swiss Type Lathe, consider factors such as:

- Size and capacity: Determine the maximum part dimensions you need to machine.

- Number of axes: Multi-axis lathes allow for more complex machining.

- Material compatibility: Ensure the lathe can handle the materials you plan to use.

- Software capabilities: Advanced programming options can enhance functionality.

6.2 Leading Manufacturers in the Market

Several manufacturers are renowned for producing high-quality CNC Swiss Type Lathes. Key players include:

- Citizen Machinery

- Star Micronics

- Tsugami

- Tornos

Researching these brands can help you identify the best machine for your specific needs.

7. Future Trends in CNC Swiss Technology

As manufacturing technology continues to advance, several trends are emerging in CNC Swiss Type Lathes. These include:

- Increased automation: The integration of robotics with CNC machines for enhanced efficiency.

- IoT connectivity: Smart manufacturing systems that allow for real-time monitoring and data analytics.

- Sustainable machining practices: The shift towards eco-friendly materials and energy-efficient processes.

These trends indicate a promising future for CNC Swiss Type Lathes in the manufacturing sector.

CNC Swiss Type Lathes have undeniably transformed the landscape of manufacturing, offering unparalleled precision, efficiency, and versatility. As industries continue to demand higher quality and faster production rates, the significance of these machines will only increase. By understanding their mechanics, applications, and future trends, manufacturers can harness the full potential of CNC Swiss Type Lathes, ultimately leading to better products and enhanced competitiveness in the market.

Related Blog