Is the Swiss Type Longitudinal Machine an Industry Model for Precision Machining

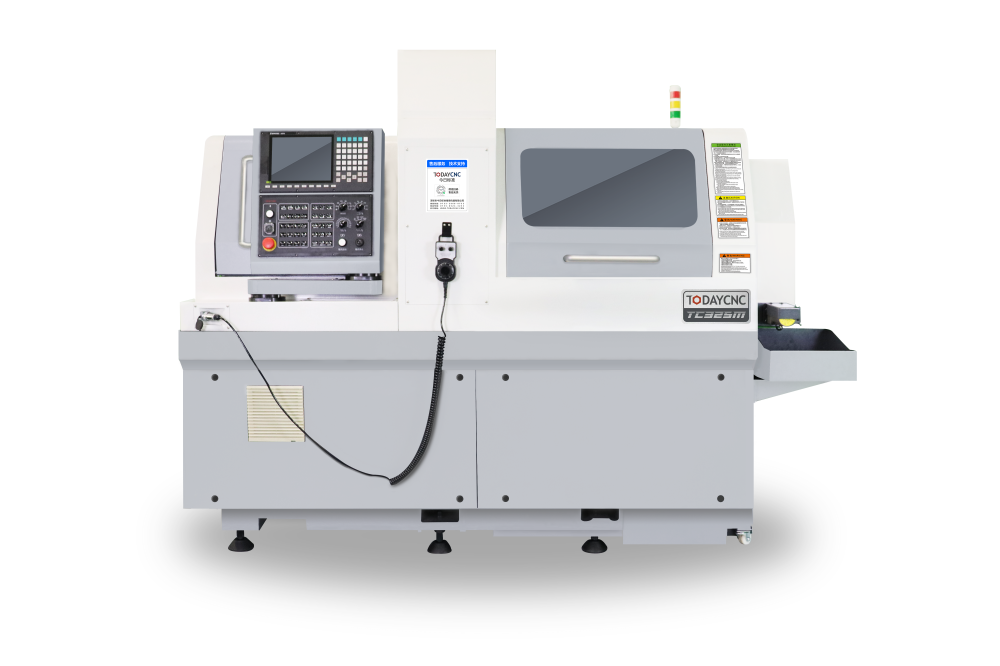

The Swiss Type Longitudinal Machine has become a benchmark in the field of precision machining worldwide with its excellent precision and high efficiency. The machine adopts an advanced longitudinal spindle design, which enables the workpiece to rotate accurately under the drive of the spindle, thereby achieving multi-angle and high-precision machining. Compared with traditional machine tools, Swiss Type Longitudinal Machines are more suitable for the production of precision parts, especially in the processing of small diameter parts and complex shapes.

The unique design of Swiss Type Machines gives them extremely high precision and stability. Whether it is small batch production or high-difficulty processes, Swiss Type Longitudinal Machines can complete complex cutting tasks in a shorter time. The CNC system of the machine can automatically adjust the tool's motion trajectory according to the set program to ensure the precise execution of each processing step. In addition, Swiss Type Machines also have good durability, and can maintain high precision and low maintenance costs even under long-term high-load operation.

The automation function of Swiss Type Longitudinal Machines greatly improves production efficiency and reduces the need for manual intervention. Through the precise CNC system, it can automatically complete multiple processing tasks, including cutting, drilling, tapping and other operations, greatly reducing the labor cost and errors in the production process. This makes it an ideal choice for high-precision parts processing in various fields, helping enterprises to realize the modernization and intelligence of production processes.

Related Blog