Unlocking Precision: The Advantages of Tailored Dual Spindle Lathes for Manufacturing Efficiency

Unlocking Precision: The Advantages of Tailored Dual Spindle Lathes for Manufacturing Efficiency

Table of Contents

- Introduction to Customized Dual Spindle Lathes

- What Are Dual Spindle Lathes?

- Benefits of Customization in Dual Spindle Lathes

- Enhanced Precision and Quality Control

- Increased Efficiency and Productivity

- Tailored Solutions for Specific Industries

- Future Trends in Dual Spindle Lathes

- Frequently Asked Questions

- Conclusion

Introduction to Customized Dual Spindle Lathes

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. Customized dual spindle lathes have emerged as a sophisticated solution for companies looking to enhance their machining operations. These machines are designed to meet specific needs, allowing manufacturers to achieve remarkable accuracy while streamlining their production processes. In this article, we will explore the intricacies of customized dual spindle lathes and how they unlock new levels of precision and productivity.

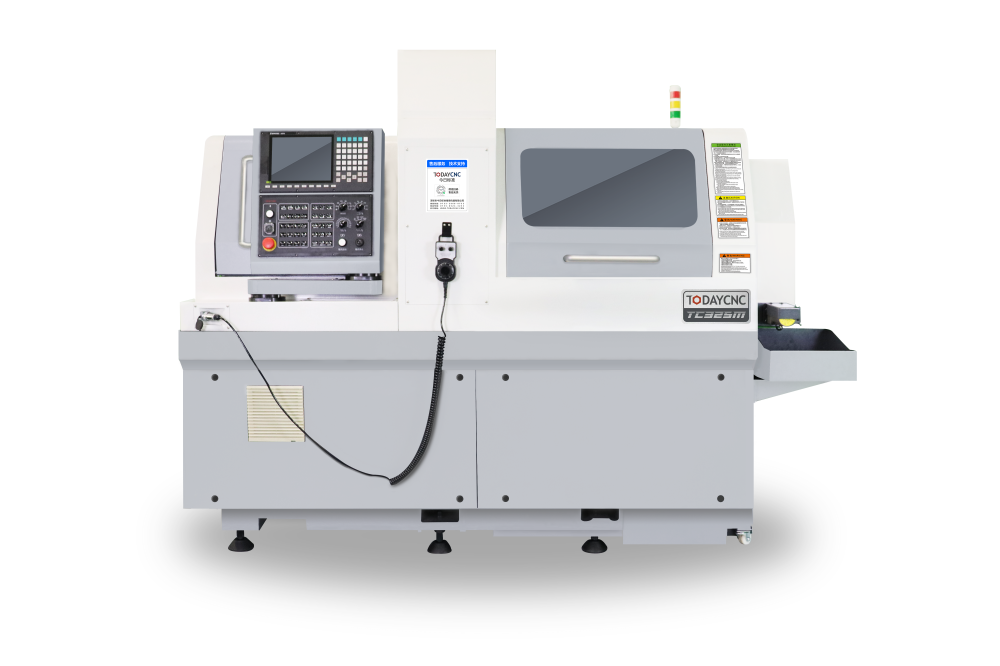

What Are Dual Spindle Lathes?

Dual spindle lathes are advanced machining tools that feature two spindles, enabling simultaneous processing of workpieces. This unique design allows for increased flexibility and operational efficiency. Unlike traditional lathes, which utilize a single spindle to perform tasks sequentially, dual spindle lathes can undertake multiple operations at once, significantly reducing cycle times and boosting overall productivity.

The Mechanics Behind Dual Spindle Lathes

The mechanics of dual spindle lathes involve two independent spindles that can operate autonomously or in tandem. Each spindle can perform different functions, such as turning, drilling, or milling, allowing manufacturers to execute complex machining tasks with a single setup. This capability not only enhances precision but also minimizes the risk of human error and increases the overall quality of the finished product.

Benefits of Customization in Dual Spindle Lathes

Customization plays a crucial role in optimizing the performance of dual spindle lathes. By tailoring these machines to meet specific operational needs, manufacturers can unlock numerous advantages that contribute to both efficiency and cost-effectiveness.

Meeting Unique Production Demands

Every manufacturing operation has distinct requirements based on the types of materials processed and the complexity of the parts produced. Customized dual spindle lathes can be designed to accommodate various materials, sizes, and shapes, ensuring that the machine aligns perfectly with the production goals.

Improved Machine Integration

Customized dual spindle lathes can be integrated into existing production lines seamlessly. This integration minimizes disruptions and allows manufacturers to leverage their current workflows while enhancing overall efficiency.

Scalability and Future-Proofing

As market demands evolve, so too must manufacturing capabilities. Customized dual spindle lathes can be designed with scalability in mind, allowing manufacturers to adapt to changing production needs without significant overhauls to their machinery.

Enhanced Precision and Quality Control

One of the most significant benefits of using customized dual spindle lathes is the enhanced precision they deliver. Precision machining is essential in industries where even the smallest deviation can lead to catastrophic failures or increased costs.

Advanced Features for Superior Accuracy

Customized dual spindle lathes can come equipped with advanced features such as adaptive control systems, high-resolution encoders, and advanced tooling options. These features work together to ensure that each machining operation is executed with unparalleled precision, resulting in high-quality parts that meet stringent industry standards.

Quality Assurance Through Automation

Automation is another aspect that enhances precision and quality control in customized dual spindle lathes. By reducing the need for manual intervention, manufacturers can minimize human error and maintain consistent quality throughout the production process. Automated inspections and real-time monitoring further ensure that parts meet quality standards before they leave the production floor.

Increased Efficiency and Productivity

Efficiency and productivity are essential to the success of any manufacturing operation. Customized dual spindle lathes can significantly enhance both metrics through their innovative design and capabilities.

Shortened Cycle Times

One of the primary advantages of dual spindle lathes is their ability to perform multiple operations simultaneously. By reducing cycle times, manufacturers can produce more parts in less time, leading to increased productivity and reduced operational costs.

Minimized Setup Changes

Customized dual spindle lathes are designed for quick and easy setup, minimizing the time required for tool changes and adjustments. This efficiency allows manufacturers to switch between different production runs without incurring significant downtime, further boosting overall productivity.

Tailored Solutions for Specific Industries

Different industries have unique challenges and requirements when it comes to machining. Customized dual spindle lathes can be tailored to meet the specific needs of various sectors, including automotive, aerospace, and medical device manufacturing.

Automotive Industry Applications

In the automotive sector, precision and speed are critical. Customized dual spindle lathes can produce complex components such as engine blocks and transmission parts with high accuracy and efficiency, helping manufacturers stay competitive in a fast-paced market.

Aerospace Industry Applications

The aerospace industry demands the highest standards of precision and quality. Customized dual spindle lathes can be designed to handle the unique materials and geometries required in aerospace applications, ensuring that critical components meet strict regulatory standards.

Medical Device Manufacturing Applications

In medical device manufacturing, precision is non-negotiable. Customized dual spindle lathes can produce intricate parts such as surgical instruments and implants with unparalleled accuracy, ensuring the safety and effectiveness of medical devices.

Future Trends in Dual Spindle Lathes

The future of dual spindle lathes is bright, with technological advancements paving the way for even greater capabilities.

Integration of Smart Technologies

As manufacturers increasingly embrace Industry 4.0, the integration of smart technologies into dual spindle lathes is a significant trend. Machine learning and IoT connectivity can enhance operational efficiency, predictive maintenance, and real-time data analysis.

Sustainability Considerations

With a growing focus on sustainability, future dual spindle lathes may incorporate energy-efficient designs and materials. Customized solutions that prioritize environmental impact will be essential as industries seek to reduce their carbon footprints.

Frequently Asked Questions

1. What components can be customized in a dual spindle lathe?

Manufacturers can customize components such as spindle speed, tool holders, and automation features to meet specific operational demands.

2. How do customized dual spindle lathes affect production costs?

By enhancing efficiency and reducing cycle times, customized dual spindle lathes can lead to lower production costs in the long run.

3. Are dual spindle lathes suitable for small batch production?

Yes, customized dual spindle lathes can be tailored for both high-volume and small batch production, providing flexibility for diverse manufacturing needs.

4. What industries benefit the most from dual spindle lathes?

Industries such as automotive, aerospace, and medical device manufacturing benefit significantly from the precision and efficiency offered by dual spindle lathes.

5. How can I determine if a customized dual spindle lathe is right for my operation?

Assess your production requirements, material types, and desired precision levels. Consulting with a specialist can help tailor a dual spindle lathe to fit your needs.

Conclusion

Customized dual spindle lathes are revolutionizing the manufacturing sector by offering tailored solutions that enhance precision, efficiency, and productivity. As industries continue to evolve, the demand for specialized machinery will only grow. By investing in customized dual spindle lathes, manufacturers can unlock new levels of operational excellence, positioning themselves as leaders in their respective markets. Embracing this technology today ensures that businesses are well-equipped to meet the challenges of tomorrow, driving innovation and growth in an increasingly competitive landscape.

Related Blog