Maximize Production Efficiency: The Advantages of Wholesale CNC Lathes with Bar Feeders

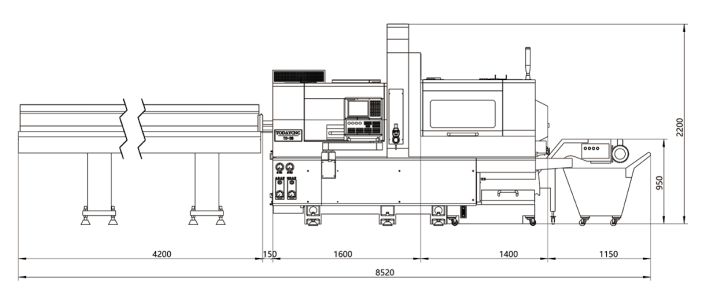

In the rapidly evolving world of manufacturing, the adoption of advanced machinery such as wholesale CNC lathes with bar feeders can significantly enhance production efficiency. These sophisticated tools are designed to automate the turning process of metal and other materials, making them invaluable assets in any machining operation.

A CNC lathe, or Computer Numerical Control lathe, is a machine that uses computer programming to control its movements and functions. The incorporation of a bar feeder allows for continuous loading of raw materials, which eliminates the need for manual handling and reduces downtime. This means that as one piece is machined, another can be fed into the system, optimizing the workflow and ensuring a steady production line.

One of the primary benefits of utilizing a wholesale CNC lathe with a bar feeder is the increase in productivity. These machines can operate for extended periods without interruption, leading to higher output rates. This is particularly advantageous for businesses that require high-volume production, as it allows them to meet customer demands more efficiently.

Moreover, the precision offered by CNC technology cannot be overstated. CNC lathes ensure that each component is manufactured to exact specifications, which minimizes the risk of errors and defects. This level of accuracy is crucial in industries where tight tolerances are necessary, such as aerospace, automotive, and medical device manufacturing. By leveraging the capabilities of a wholesale CNC lathe with a bar feeder, manufacturers can achieve superior quality in their products.

Another notable advantage is the enhanced adaptability of these machines. Modern CNC lathes can be programmed for various tasks, enabling manufacturers to switch between different production runs with relative ease. This versatility, combined with the efficiency of a bar feeder, allows businesses to respond swiftly to changing market demands and diversify their product offerings without significant downtime.

Furthermore, the integration of CNC lathes with bar feeders contributes to improved safety in the workplace. By automating the loading process, the risk of operator injury is significantly reduced. As machines handle the repetitive tasks, workers can focus on more critical aspects of production, ultimately fostering a safer and more productive environment.

In conclusion, wholesale CNC lathes with bar feeders represent an essential investment for manufacturers seeking to enhance their operational efficiency. With the ability to increase productivity, ensure precision, and improve workplace safety, these machines are pivotal in the modern manufacturing landscape. Companies that embrace this technology not only streamline their processes but also position themselves for sustained growth in an increasingly competitive market. Embracing such innovations is not just a trend; it is a necessary step towards future success in manufacturing.

A CNC lathe, or Computer Numerical Control lathe, is a machine that uses computer programming to control its movements and functions. The incorporation of a bar feeder allows for continuous loading of raw materials, which eliminates the need for manual handling and reduces downtime. This means that as one piece is machined, another can be fed into the system, optimizing the workflow and ensuring a steady production line.

One of the primary benefits of utilizing a wholesale CNC lathe with a bar feeder is the increase in productivity. These machines can operate for extended periods without interruption, leading to higher output rates. This is particularly advantageous for businesses that require high-volume production, as it allows them to meet customer demands more efficiently.

Moreover, the precision offered by CNC technology cannot be overstated. CNC lathes ensure that each component is manufactured to exact specifications, which minimizes the risk of errors and defects. This level of accuracy is crucial in industries where tight tolerances are necessary, such as aerospace, automotive, and medical device manufacturing. By leveraging the capabilities of a wholesale CNC lathe with a bar feeder, manufacturers can achieve superior quality in their products.

Another notable advantage is the enhanced adaptability of these machines. Modern CNC lathes can be programmed for various tasks, enabling manufacturers to switch between different production runs with relative ease. This versatility, combined with the efficiency of a bar feeder, allows businesses to respond swiftly to changing market demands and diversify their product offerings without significant downtime.

Furthermore, the integration of CNC lathes with bar feeders contributes to improved safety in the workplace. By automating the loading process, the risk of operator injury is significantly reduced. As machines handle the repetitive tasks, workers can focus on more critical aspects of production, ultimately fostering a safer and more productive environment.

In conclusion, wholesale CNC lathes with bar feeders represent an essential investment for manufacturers seeking to enhance their operational efficiency. With the ability to increase productivity, ensure precision, and improve workplace safety, these machines are pivotal in the modern manufacturing landscape. Companies that embrace this technology not only streamline their processes but also position themselves for sustained growth in an increasingly competitive market. Embracing such innovations is not just a trend; it is a necessary step towards future success in manufacturing.

Related Blog