Understanding Swiss Type Longitudinal Machines: A Comprehensive Guide

Swiss type longitudinal machines, commonly known as Swiss lathes, are specialized turning machines designed for the production of small, precise components. These machines are pivotal in the manufacturing and machining industry, particularly for tasks that require high accuracy and minimal waste. The unique design of Swiss lathes allows for the efficient creation of intricate parts, making them an essential tool in various sectors such as aerospace, automotive, and medical device manufacturing.

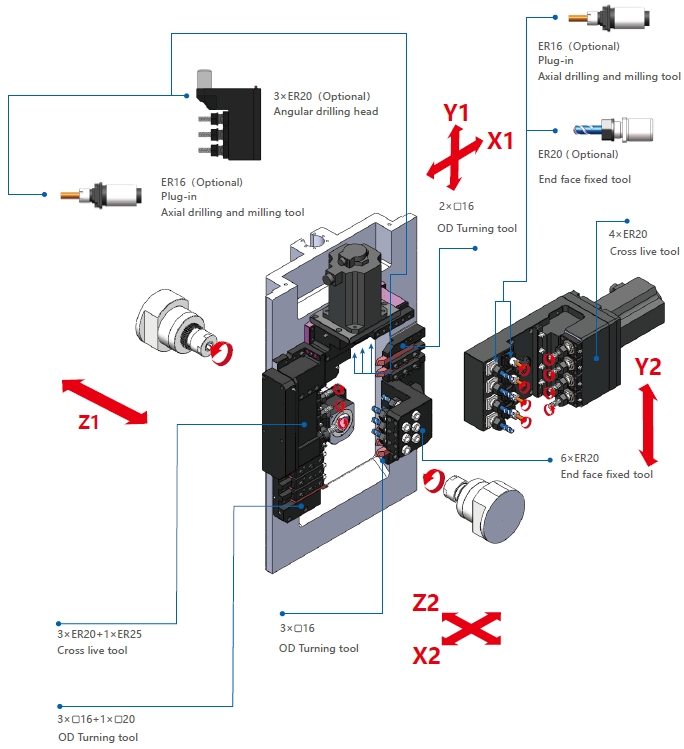

One of the defining characteristics of Swiss type longitudinal machines is their ability to produce complex shapes through a combination of turning and milling operations. This is achieved by using a sliding headstock that can move the workpiece closer to the cutting tool, allowing for better support of long, slender parts during the machining process. As a result, Swiss lathes are particularly adept at producing long, thin components that traditional lathes may struggle with, minimizing the risk of vibration and ensuring high-quality surface finishes.

Another advantage of Swiss type longitudinal machines is their impressive speed and efficiency. These machines are designed to operate continuously, reducing the cycle time for part production. This is especially beneficial for high-volume manufacturing, where time savings can significantly impact overall production costs. Additionally, the automation features commonly found in modern Swiss lathes, such as programmable controls and automatic bar loaders, further enhance their productivity.

Precision is a hallmark of Swiss lathes. The machines are engineered to achieve tight tolerances, often within fractions of a millimeter. This level of accuracy is crucial in industries that demand strict quality control, such as medical device manufacturing, where even the smallest deviation can lead to significant issues. The ability to maintain consistent quality over large production runs makes Swiss type longitudinal machines a preferred choice for manufacturers aiming for reliability and excellence.

Furthermore, Swiss lathes are versatile. They can accommodate a wide range of materials, including metals, plastics, and composites. This adaptability allows manufacturers to utilize Swiss type longitudinal machines for various applications, from creating simple fasteners to complex components used in advanced technology.

In summary, Swiss type longitudinal machines are invaluable tools in the realm of manufacturing and machining. Their unique design, efficiency, precision, and versatility make them a go-to solution for producing high-quality, intricate components. As industries continue to evolve and demand higher standards, the role of Swiss lathes in meeting these challenges cannot be overstated. By understanding their capabilities and applications, manufacturers can better appreciate the significant contributions these machines make to modern production processes.

One of the defining characteristics of Swiss type longitudinal machines is their ability to produce complex shapes through a combination of turning and milling operations. This is achieved by using a sliding headstock that can move the workpiece closer to the cutting tool, allowing for better support of long, slender parts during the machining process. As a result, Swiss lathes are particularly adept at producing long, thin components that traditional lathes may struggle with, minimizing the risk of vibration and ensuring high-quality surface finishes.

Another advantage of Swiss type longitudinal machines is their impressive speed and efficiency. These machines are designed to operate continuously, reducing the cycle time for part production. This is especially beneficial for high-volume manufacturing, where time savings can significantly impact overall production costs. Additionally, the automation features commonly found in modern Swiss lathes, such as programmable controls and automatic bar loaders, further enhance their productivity.

Precision is a hallmark of Swiss lathes. The machines are engineered to achieve tight tolerances, often within fractions of a millimeter. This level of accuracy is crucial in industries that demand strict quality control, such as medical device manufacturing, where even the smallest deviation can lead to significant issues. The ability to maintain consistent quality over large production runs makes Swiss type longitudinal machines a preferred choice for manufacturers aiming for reliability and excellence.

Furthermore, Swiss lathes are versatile. They can accommodate a wide range of materials, including metals, plastics, and composites. This adaptability allows manufacturers to utilize Swiss type longitudinal machines for various applications, from creating simple fasteners to complex components used in advanced technology.

In summary, Swiss type longitudinal machines are invaluable tools in the realm of manufacturing and machining. Their unique design, efficiency, precision, and versatility make them a go-to solution for producing high-quality, intricate components. As industries continue to evolve and demand higher standards, the role of Swiss lathes in meeting these challenges cannot be overstated. By understanding their capabilities and applications, manufacturers can better appreciate the significant contributions these machines make to modern production processes.